| Proto Typing Center (PTC) / Foundry service |

|---|

Sumitomo Precision Products group has supplied MEMS foundry service for 6/8 inches wafers through one of affiliated companies, Silicon Sensing Systems in the past. MSMS∞expands previous functions of the foundry service. In this expansion, sales contact for foundry service is transferred to Sumitomo Precision Products. We will provide a consistent support which consists of 2 main functions, “MEM proto typing center” for prototyping and “MEMS foundry service” for volume production in addition to functions of “Design and development services” and “Consulting”.

Device design analysis・Consulting

For customers who develop and produce devices at foundry, we are planning to launch MEMS∞ design center in year 2024, at which various kind of design analysis simulators are installed additionally. This is for sharing widely design know-how such as results from device structure analysis by ANSYS Enterprise which we have accumulated for our own products so far.

Device development and prototyping・device volume production

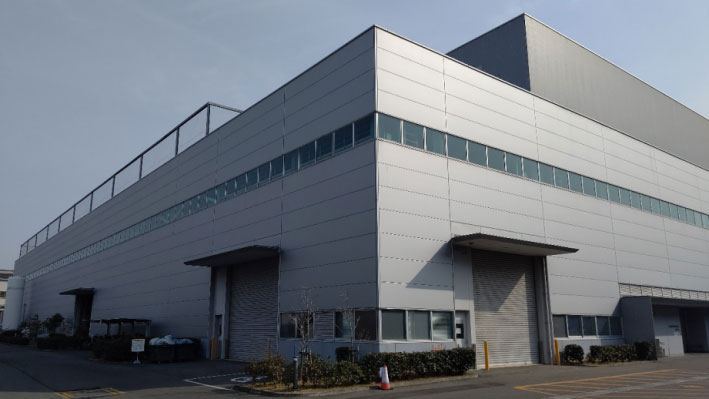

Prototyping and volume production o devices are provided at MEMS wafer fab for 6/8 inches wafers where is in Amagasaki head office factory (Operated by Silicon Sensing Products). We have many proven record for piezo electronic films (PZT thin film) which is our strong point. And as for Si deep RIE process, we provide manufacturing process optimized for each devices with volume production level by working together with SPP Technologies Co., Ltd., which is one of our affiliate companies.

In addition, MEMS∞ is planning to introduce processing equipment which Silicon Sensing Systems does not have before in year 2025 as our target in order to address to various needs from customers.

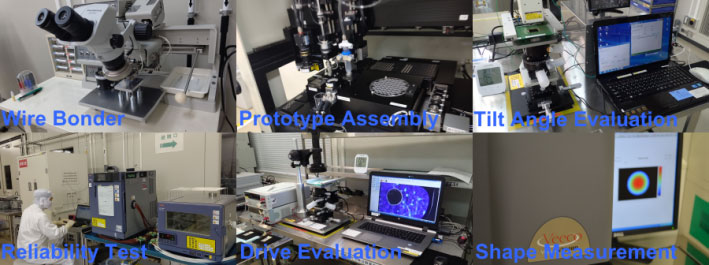

Consultation for device prototyping and evaluation

We have a clean room with 350m2 dedicated for device development and extensive equipment for evaluation for various kind of devices. For the customers who are planning to prototype for volume production, if required, we analyze with die packaging and offer consultation for issues by supply of final devices. It is also possible to provide feedback obtained data to design.

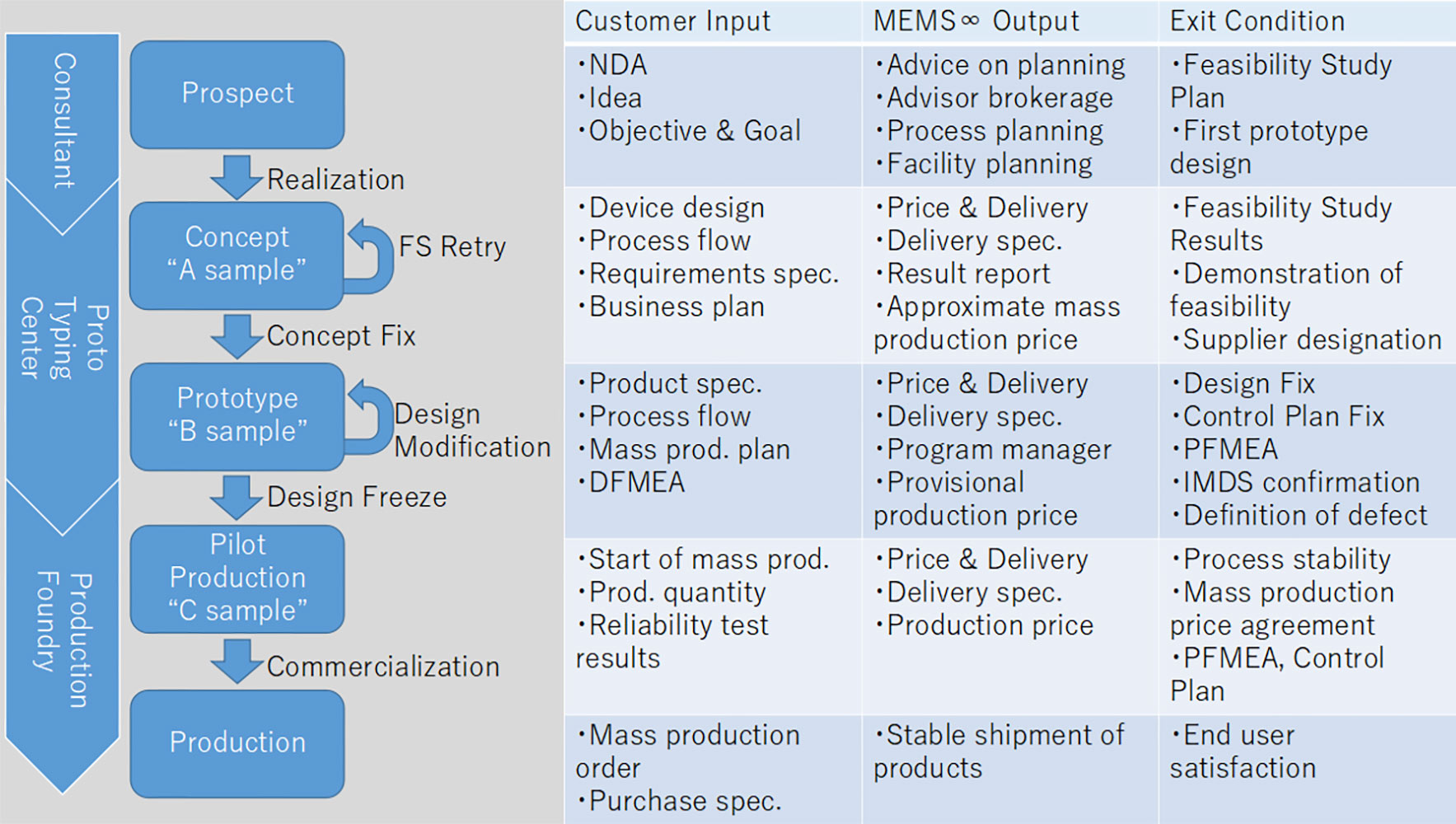

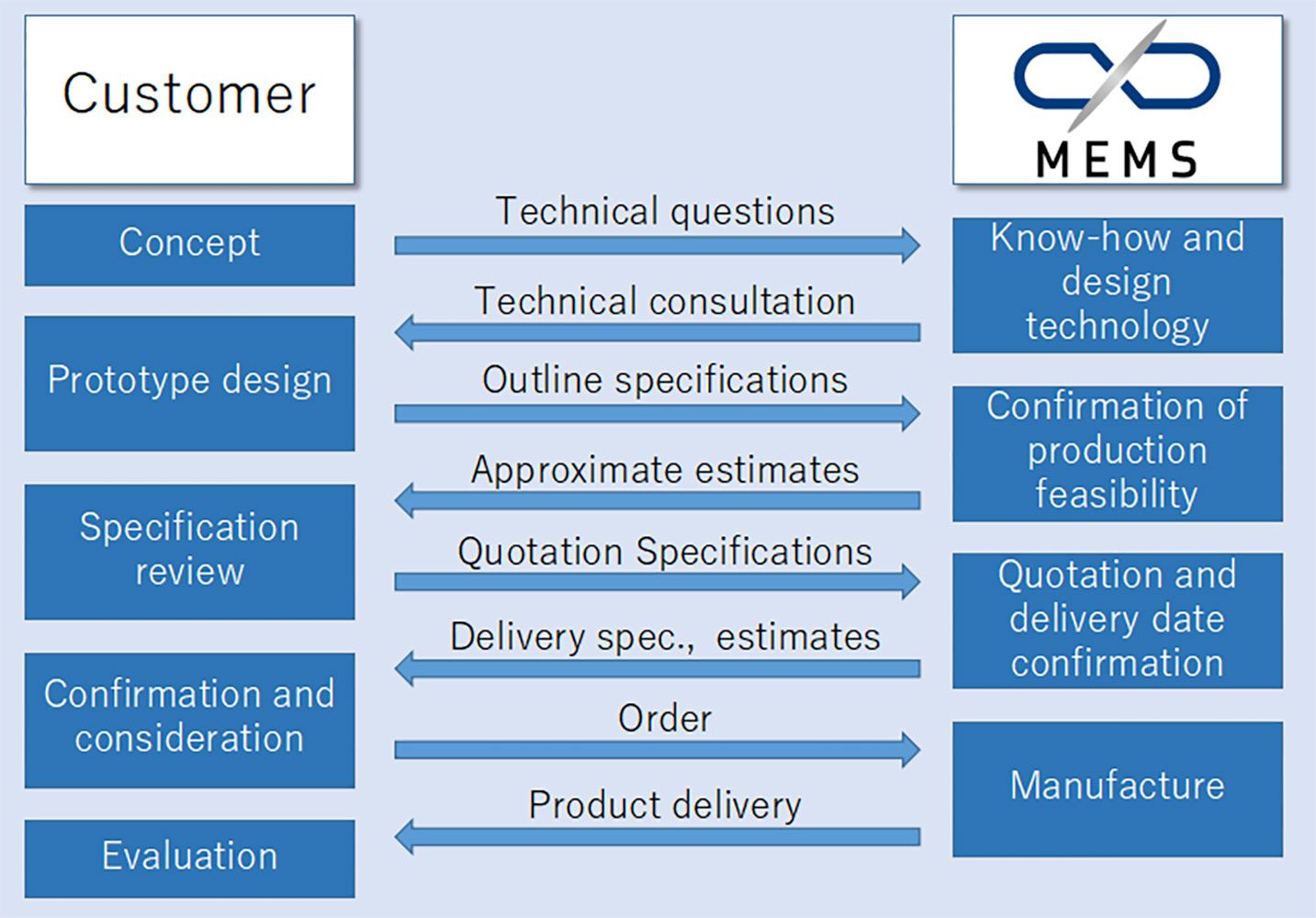

Service flow in PTC

APQP for MEMS volume production foundry

Sumitomo Precision Production group has a policy of holding quality management system at each division.

Newly established MEMS∞ is also planning to obtain quality management system for transferring to volume manufacturing of customer’s device.