MEMS-AHRSNorthfinder™

A highly Sensible MEMS gyroscope and a newly developed algorithm enable FOG-level high precision and real-time true north detection! Easy to use and significantly reduced costs, with a compact, high durable, and power-saving design

Northfinder™ Lineup & Uses

Lineup

Northfinder A(GCAH-12)

- External dimensions

- 36×43×266(mm)

- Mass

- 700g

- Compact design

- The smallest of the Northfinder products and is perfect for built-in use.

- Three grades available

- There are three grades to choose from according to the accuracy of the static angle (azimuth). (Premium/Special/Regular)

| Item | Value | |||

|---|---|---|---|---|

| Premium | Special | Regular | ||

| Static angles Azimuth | Range | ±180° | ||

| Accuracy | ±0.8° × (cos λ · cos θ)^-1 (1σ) (λ: Latitude) *1 | ±1.5° × (cos λ · cos θ)^-1 (1σ) (λ: Latitude) *1 | ±2.5° × (cos λ · cos θ)^-1 (1σ) (λ: Latitude) *1 | |

| Attitude | Range | Pitch(θ): ±90°, Roll(ϕ): ±180° | ||

| Offset error | Pitch: < ±0.1°rms × (cos θ)^-1 | |||

| Repeatability | Pitch: < ±0.02° (1σ), Roll: < ±0.02° × (cos θ)^-1 (1σ) | |||

| Dynamic angles Azimuth Attitude | Error | < 0.5% max. (Without angle drift) | ||

| Resolution | < 0.05° | |||

| Angle drift | < 2°/h max. | < 3°/h max. | < 5°/h max. | |

| Settling time | 1.5 minutes (under static condition) | |||

| Electrical Interface | D-sub 15 | |||

| Communication protocol | RS-422 (Baud rate: 230.6 kbps) | |||

| Size & Weight | 36 x 43 x 266 mm, (Φ30 x 257 mm), 0.7 kg | |||

| Power supply | 6.5 to 24 VDC (Typical 12 VDC) | |||

| Power consumption | < 1.5 W | |||

| Temperature range | -20 to 65 °C (Operation & Storage) | |||

A new model is currently in development!

We are also developing a different type of Northfinder.

Detailed information will be released as it becomes available

Recommended Uses

-

Downhole drilling survey

-

High-precision output of vessel attitude and movement

-

Travel path mapping

-

Oil & Gas downhole drilling industry

-

Measurement of attitude and motion of underwater construction equipment such as underwater backhoes

-

Measurement of attitude and motion of Autonomous Underwater Vehicle(AUV)

-

Remote monitoring of track distortion in railways

-

Controlling the position of construction machinery

- etc.

Datasheet Download

Northfinder™ Lineup & Uses

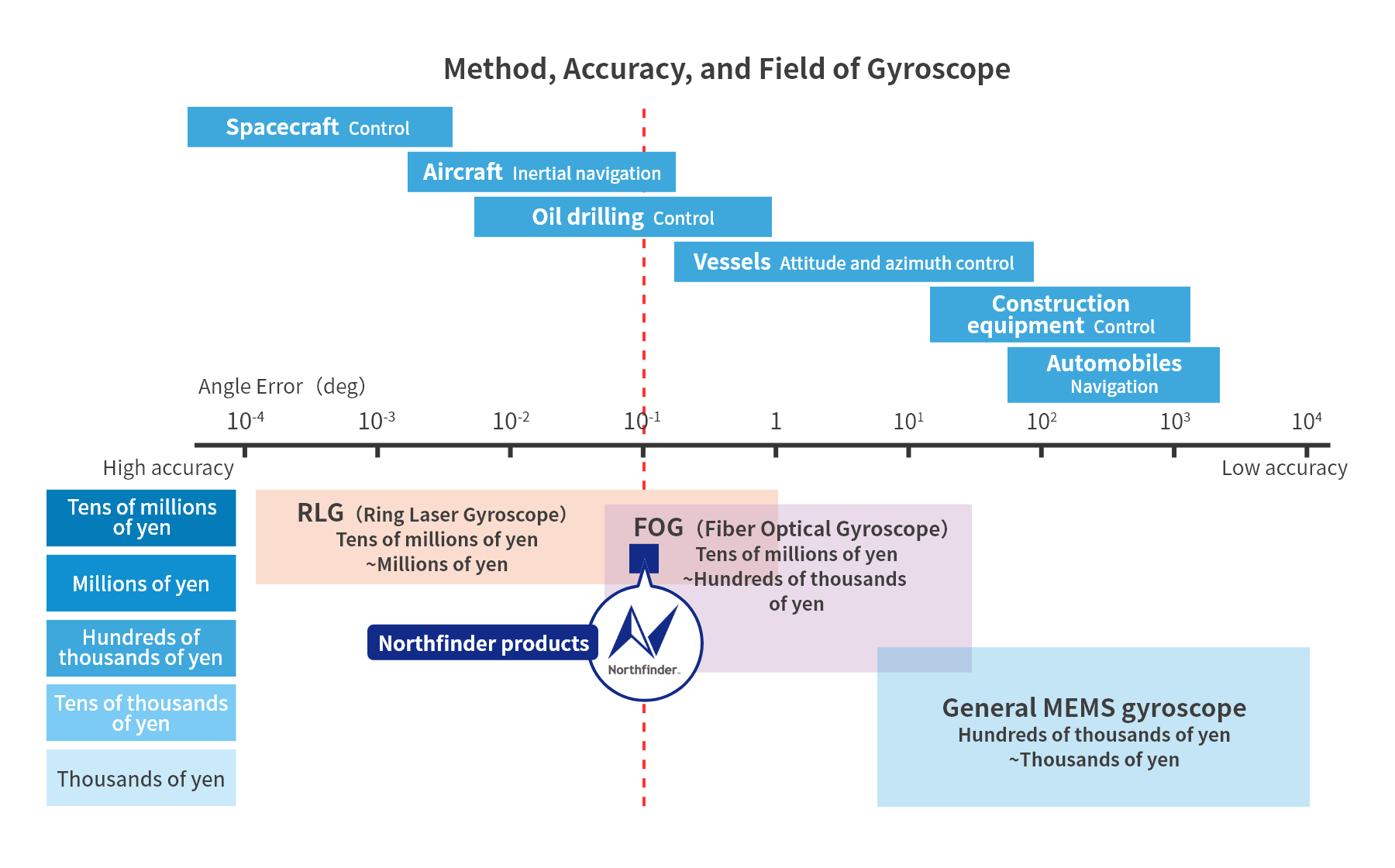

Changing the conventional wisdom that high-precision attitude angle and azimuth measurements require FOG*1 and RLG*2. That's Northfinder™.

Sumitomo Precision Products' Northfinder is a revolutionary technology that combines a highly Sensible MEMS gyroscope with a newly developed algorithm to measure the Earth's rotation angular velocity in real time.

Products with Northfinder technology provide attitude angle information with a high degree of accuracy comparable to FOG and RLG. While a MEMS gyroscope, Northfinder is also capable of detecting true north without relying on GPS.

*1 Fiber Optical Gyroscope

*2 Ring Laser Gyroscope

About Northfinder™

Reasons for Recommending Northfinder™

Attitude angle accuracy at initial stabilization with an error of 0.1°

Generally, the error in accuracy of the attitude angle (pitch angle and roll angle) of a gyroscope is the smallest after initial stabilization in each of the MEMS, FOG, and RLG systems, and it increases with time. Northfinder products can reduce the error after initial stabilization to the same level as FOG, and their accuracy is orders of magnitude higher than that of typical MEMS gyroscopes.

Since the increase in error with time is maintained at a constant amount, the accuracy can exceed even FOG over time.* In addition, by incorporating transfer speed data, it is possible to further reduce the error over time,* making it ideal for use on railways and other mobile objects.

* The accuracy varies depending on the conditions of use, the environment, and the performance of the products being compared.

Small and lightweight size utilizing MEMS

Costs less than half of FOG and RLG

The MEMS gyroscope used in Northfinder products is very small because it uses a semiconductor process.

Since it can be manufactured in large quantities and inexpensively, the product costs much less than FOG or RLG.

Easy to handle and flexible operation available

The MEMS gyroscope used in Northfinder products has an excellent anti-vibration and anti-shock structure. These features make it much easier to handle than FOG or RLG. Also, the MEMS structure is very small and does not require much power to operate, so the power consumption is much lower, about 1/10 compared to FOG or RLG. It can also be powered by a mobile battery and can be used as a standalone or flexible operating system.

Northfinder™ Strengths

Obtain absolute azimuth where GPS is not available.

Assist/complement GPS

The highly Sensible MEMS gyroscope allows Northfinder products to sense the Earth's axis of rotation and detect true north in real time. The error in accuracy of absolute azimuth and yaw angles is 1.5° after initial stabilization, which is less than 1/10 of general MEMS gyroscopes. The error over time is also kept as low as 2°/h.

In addition, the error over time is reset by performing initial stabilization at any time. When used in equipment that requires brief measurements or work that stops periodically, performing initial stabilization after each stop ensures stable accuracy.

About Sumitomo Precision Products

Sumitomo Precision Products have started to develop and manufacture MEMS in the 1990s, and produce gyroscopes equipped with MEMS in 2000. It has been used in electronic stability control systems in automobiles and has been highly evaluated in terms of safety.

Our products have a different design from other companies' products and are characterized by their ability for high precision accuracy, and we have been working on research to improve accuracy since around 2010.

The high-precision MEMS gyroscope is already installed as a sensor for attitude control and guidance control for navigation of space rockets.

Compared to the Ring Laser Gyro (RLG) that has been used conventionally, it is lighter and consumes less power, and the manufacturing cost is much lower, so it is expected increase in the future.

We are developing and manufacturing a variety of products by applying the technologies we have cultivated to date.

Glossary & FAQ

Click on the item for a detailed description

- What is MEMS?

- MEMS stands for Micro Electro Mechanical Systems. They are devices made by utilizing and advancing the microfabrication technology that has been developed and established for the production of semiconductors on Si wafers. However, instead of two-dimensional integrated circuits (LSI), MEMS devices have a three-dimensional mechanical structure.

- What is AHRS?

- AHRS stands for Attitude Heading Reference System, which is a device that outputs attitude angle and absolute azimuth angle.

- What is attitude angle?

- Refers to the angle of rotation per unit of time. The units are degree/sec (second) or degree/hour (hour).

- What is attitude angle?

- The attitude angle is the inclination of the object relative to the plane containing the X and Y axes perpendicular to the Earth's gravitational axis (Z axis).

- What is azimuth angle?

- The azimuth angle is the angle about the Earth's gravitational axis, which is perpendicular to the XY plane. There is the relative azimuth angle, in which the initial azimuth angle the equipment is pointing in when it is switched on is taken as zero degrees, and the absolute azimuth angle, in which the true north (North Pole) direction is taken as zero degrees. All products can measure the relative azimuth angle, but the NorthFinderTM products can also measure the absolute azimuth angle.

- What is bias?

- Any type of sensor will have a zero point error for the physical quantity (true value) being sensed. Bias is the error that occurs when the target physical quantity is zero.

- What is drift?

- Drift refers to the sensor output changing over time. Drift may occur with a time constant of a few seconds to a few minutes after the sensor power supply is turned on, or may occur in units of several months.

- What are the main uses for gyros?

- This device is used to detect the movement of objects, so it can be used for the purpose of detecting the movement of moving objects. In addition, NorthFinderTM can also detect the azimuth angle in environments where GNSS signals cannot be received, so it can be used as an optimal substitute for GNSS in environments such as underground and underwater.

- What are the operating principles of a MEMS gyro?

- The MEMS gyros from Sumitomo Precision Products are what is called the vibration type. There is primary vibration on ring-shaped silicon vibrators in the directions of 0, 90,180 and 270 degrees. When an angular velocity (rotation) is applied in that state, a secondary vibration that is proportional to the angular velocity occurs in the direction that is 45 degrees from the primary vibration. That secondary vibration is read to measure the angular velocity. See here for more details.

- What are the advantages over RLG (Ring Laser Gyros)/FOG (Fiber Optic Gyros)?

- On RLG (Ring Laser Gyros) and FOG (Fiber Optic Gyros), the angular velocity is detected by using the phase shifts in the light traveling in opposite directions over a certain optical path length. RLG and FOG are very accurate, but they are very complex, so they are relatively large and expensive to manufacture. Semiconductor processes are applied to produce MEMS gyros, so they are very small and can be manufactured in large quantities. As a result of this, it is possible to manufacture them at a lower cost than gyros that use light. In addition, the MEMS structure is very small, and there are no elements that require a large amount of power, such as a laser, so a MEMS gyro can operate at 1/10 the power consumption of a gyro that uses light.

- What is the measurement principle for true north?

- It is obtained by measuring the rotation axis of the Earth with the gyro. True north and the axis of rotation are almost the same.

- Is true north different from magnetic north?

- Magnetic north is obtained by measuring geomagnetism with a magnetic sensor. In the central area of Japan, it differs from true north by about 7 degrees.

- There are small products on the market that have an IMU function in one chip.

- Even in a product that has an IMU function in one chip, the X, Y, and Z axis elements are arranged independently inside the chip, and the accuracy of the Z axis element in particular is relatively poor. In our gyros, in order to give the products their characteristic high accuracy in any position, the IMU is composed of independent gyros with the same structure in all of the X, Y, and Z axes. This makes the size larger than IMU in one chip, but they are characterized by high accuracy.

- How are the gyros and applied products from Sumitomo Precision Products superior to those from other companies and what are the advantages of installing them?

- On our gyroscope, a silicon ring type resonator is resonated and vibrated to form an ellipse, and the angular velocity is obtained based on the Coriolis force that is generated there. A typical MEMS gyro has the advantage of being small and inexpensive, but when vibration such as that due to an external impact occurs, the resonant vibration can be disturbed by the external vibration and result in an incorrect output. In contrast with this, when a ring shape is used, the disturbance to the vibration of the ring due to the external vibration is very small, so this type is superior against vibration and impacts. In addition, on the applied products that use the gyro, in order to make the most of the characteristics of a gyro, in addition to the characteristics explained above, the products are also characterized by the use of proprietary algorithms of our company that mean that even with a MEMS gyro, it is possible to detect true north by measuring the rotational angular velocity of the Earth. A characteristic obtained by using the MEMS type is that the power consumed is 1/10 that consumed by other gyrocompasses. This is a great advantage, particularly when a product is powered by a battery.