Products

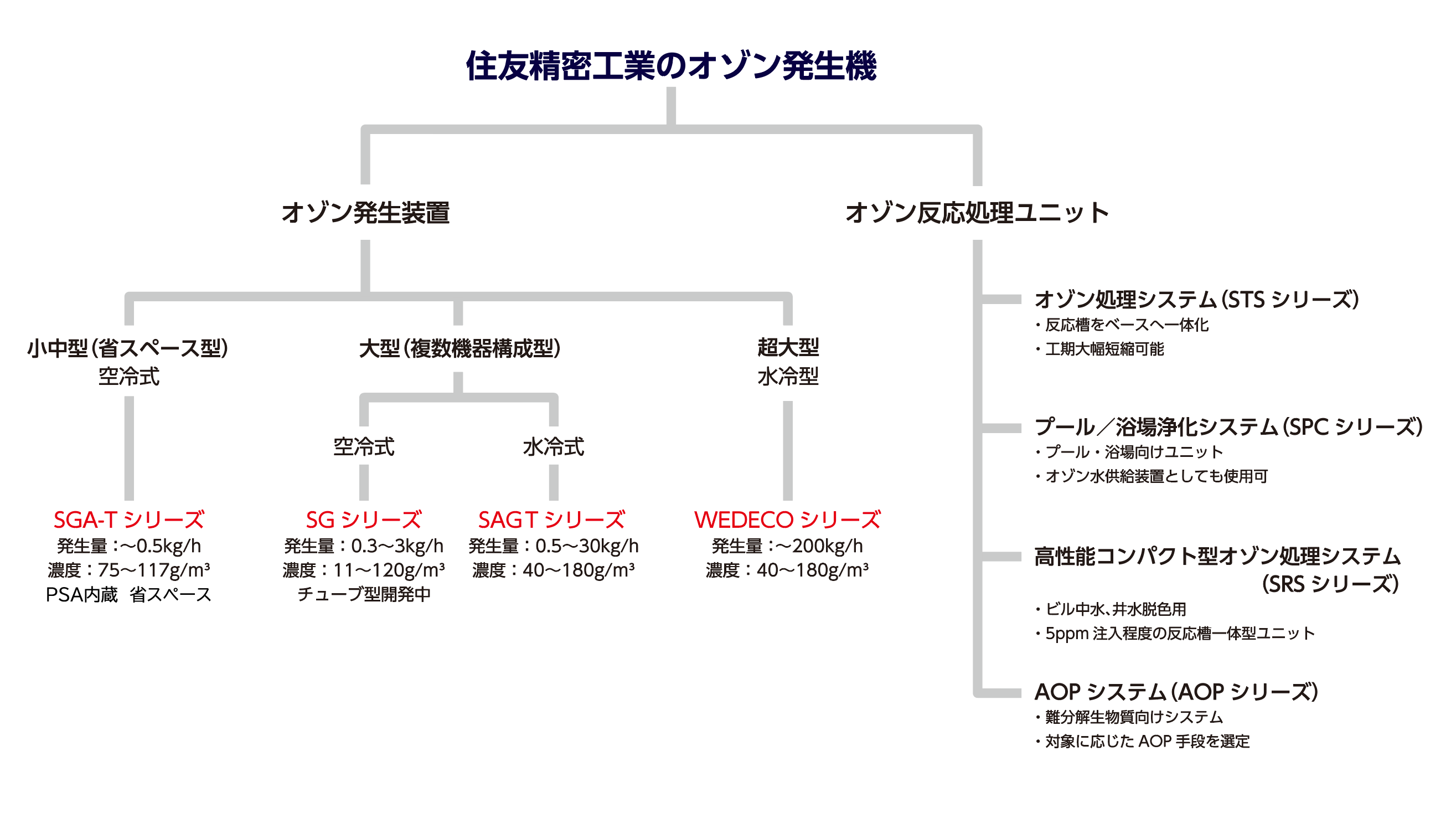

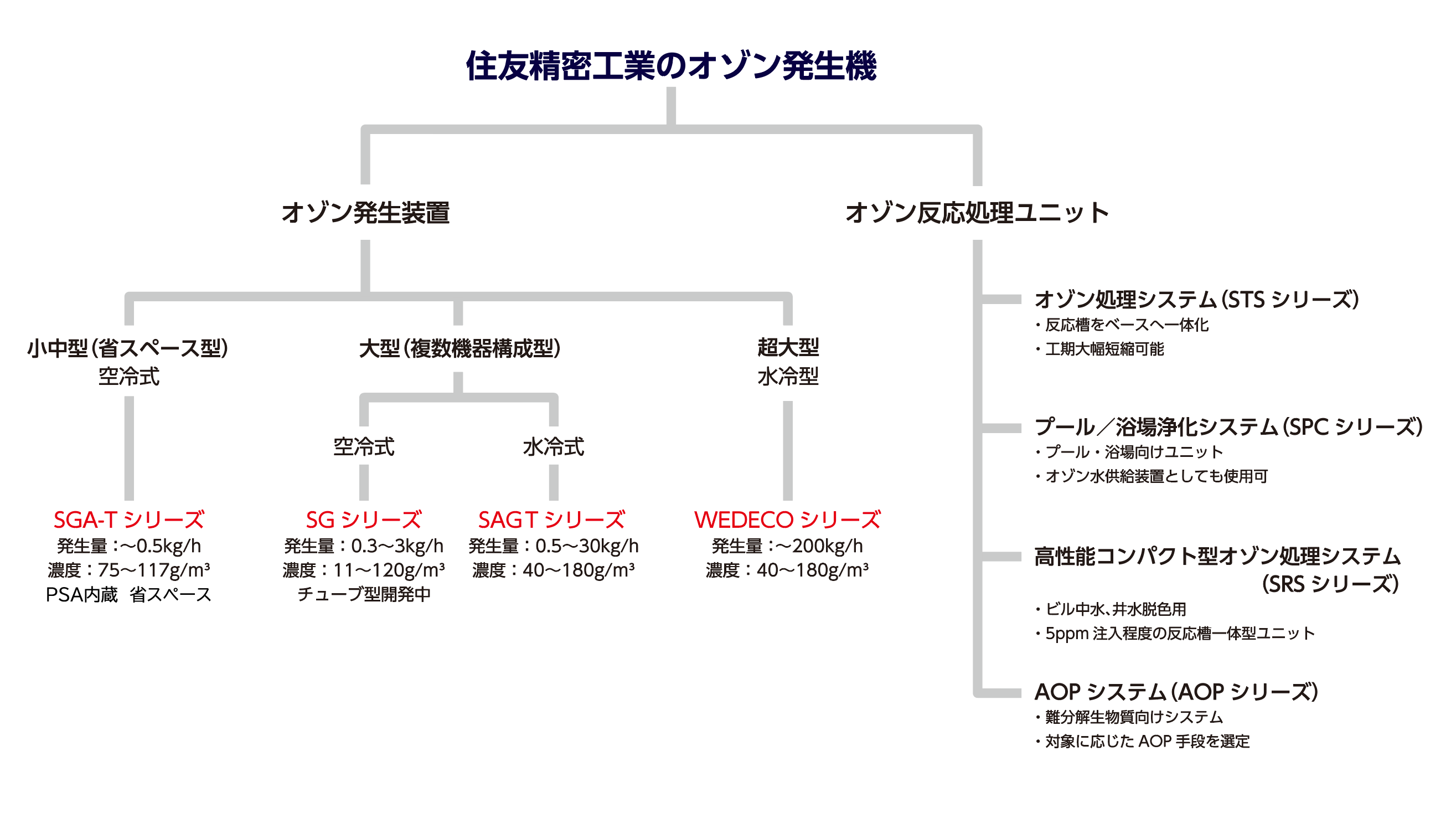

Ozone Generator

Our company is a pioneer in the manufacture of ozone generators, with a history dating back to 1974.

We will propose the most suitable ozone generator and ozone generation system depending on the usage environment and application. We also accept consultations regarding special specifications.

SGA-T Series

Click here for the special website for the new PSA ozonizer

| Specification |

| Ozone generation amount |

5 to 500 g/h |

| Ozone gas concentration |

75 to 117 g/m 3 (N) |

| Ozone gas flow rate |

2~90L/min |

| Cooling method |

Air-cooled |

| Accessory equipment |

Built-in compressor and PSA oxygen generator

(Compressor included for 50g/h or more) |

| Features |

Compact, simple and space-saving

Air-cooled for easy operation and maintenance

The raw material gas is oxygen generated from the built-in PSA.

No oxygen supply equipment required |

High concentration ozone

High-concentration ozone can be easily obtained using PSA oxygen as the raw material. |

Variable ozone concentration

Adjustable volume allows free control between 0 and 100% |

SG Series

| Specification |

| Ozone generation amount |

130g/h to 3kg/h |

| Ozone gas concentration |

Raw gas: Air: 11-15g/m 3 (N) |

| Raw material gas: PSA oxygen: 100-120g/m 3 (N) |

| Ozone gas flow rate |

2.1 to 240 m3 /h |

| Cooling method |

Air-cooled |

| Accessory equipment |

Compressor, air purifier or PSA oxygen generator

Defoaming tower, ozone decomposition tower |

| Features |

| Air-cooled ozonizer that is easy to operate and maintain |

Variable ozone concentration

Adjustable volume allows free control between 0 and 100% |

SAGT Series

| Specification |

| Ozone generation amount |

500g/h to 30kg/h |

| Ozone gas concentration |

Raw material gas: Air: 40g/m 3 (N) |

| Raw material gas: Oxygen: 120, 150/m 3 (N) |

| Ozone gas flow rate |

2.4 to 100 m3 /h |

| Cooling method |

water cooled |

| Accessory equipment |

Compressor, air purifier or PSA oxygen generator

Chiller or heat exchanger

Defoaming tower, ozone decomposition tower |

| Features |

| Small diameter cylindrical multi-tube discharge method |

| Compact design with small diameter discharge tube |

| 13% reduction in running costs (compared to our previous model) due to the adoption of a highly efficient discharge method |

WEDECO series

| Specification |

| Ozone generation amount |

30kg/h or more |

| Ozone gas concentration |

Raw material gas: Air: 40g/m 3 (N) |

| Raw material gas: Oxygen: 150, 180g/m 3 (N) |

| Cooling method |

water cooled |

| Accessory equipment |

Compressor, air purifier or oxygen generator

Chiller or heat exchanger

Defoaming tower, ozone decomposition tower |

| Features |

| Large water-cooled ozonizer customized for domestic use |

| Japan's largest capacity of 400 kg/h |

Ozone Treatment System

When using an ozone generator for water treatment, an ejector to dissolve the ozone, a pump, a reaction tank, a gas-liquid separator, and an ozone decomposer are required.

We offer products that incorporate the above into a system.

SPC Series

| Specification |

| Ozone generation amount |

10 to 140 g/h |

| Treated water volume |

1.5 to 50 m3 /h |

| Ozone injection method |

Ejector system |

| Onboard equipment |

Ozone generator (SGA-T series), pressure pump, ejector

Gas-liquid separator, exhaust ozone decomposer, valves and valve sets |

| option |

UV, seawater specifications, various ozone monitors |

| Features |

| High ozone reaction efficiency thanks to our own designed ejector |

| No need for ozone treatment equipment due to the inclusion of an ozone decomposer |

| Highly efficient gas-liquid separation tower in a compact device enables large-volume water treatment |

| Purpose |

| Pool |

| Aquarium |

| zoo |

| Ozone water generation |

STS Series

| Specification |

| Ozone generation amount |

50 to 500 g/h |

| Treated water volume |

5 to 500 m3 /h |

| Ozone injection method |

Ejector system |

| Onboard equipment |

Ozone generator (SGA-T series), pump, ejector

Retention reactor, exhaust ozone decomposer, valves and valve set |

| option |

UV and various ozone monitors |

| Features |

| High ozone reaction efficiency thanks to our own designed ejector |

| Ozone decomposition unit |

| Unit-based construction allows for shorter construction times |

| Purpose |

| Small-scale wastewater |

| Recycled water (recycled water from buildings, etc.) |

| Water treatment for hydrophilic and landscaping purposes |

SRS Series

| Specification |

| Ozone generation amount |

35 to 150 g/h |

| Processing flow rate |

7 to 30 m³/ h |

| Ozone injection method |

Ejector system |

| Onboard equipment |

Ozone generator (SGA-T series), pressure pump

Gas-liquid separator, exhaust ozone decomposer, ejector, valves and valves |

| option |

Various ozone monitors, ultraviolet rays |

| Features |

| Space-saving |

| High performance, high functionality, compact size, and sufficient ozone reaction efficiency |

| Easy to install |

| Purpose |

| Well water purification |

| Industrial Water Purification |

| Recycled water (recycled water from buildings, etc.) |

AOP Series

| Specification |

| Ozone generation amount |

10 to 1,000 g/h |

| Treated water volume |

1 to several hundred m3 /day |

| Ozone injection method |

Ejector system |

| Onboard equipment |

Ozone generator, UV light,

Pumps, ejectors

Gas-liquid separator, exhaust ozone decomposer, valves and valve set |

| Features |

| By using an optimal combination of ozone, ultraviolet light, etc., biodegradable substances are broken down into smaller molecules and decomposed to extremely low concentrations. |

| Purpose |

| Decomposition of persistent substances (dioxins, dioxane, VOCs, etc.) |

| Recycled water, etc. |