BUSINESS

Business Overview

Aerospace business

We are creating

the safety and future of the sky.

landing gear We develop and manufacture products that are directly involved in aircraft flight safety, such as the Aerospace Thermal Management system and . Almost all of our leg systems for Ministry of Defense are used in domestically produced aircraft. In the field of commercial aircraft, we entered the regional aircraft market in 1997 with an order from Bombardier Inc. in Canada for leg systems for the CRJ700 in cooperation with Menasco Contracting L.L.C. For thermal control systems for aircraft engines and air conditioning equipment, we have developed thermal control systems for the engines of the B787 dream liner and Rolls-Royce plc installed on the A350, and oil coolers for the auxiliary power unit (APU) installed on the B787 dream liner.

Main products and features

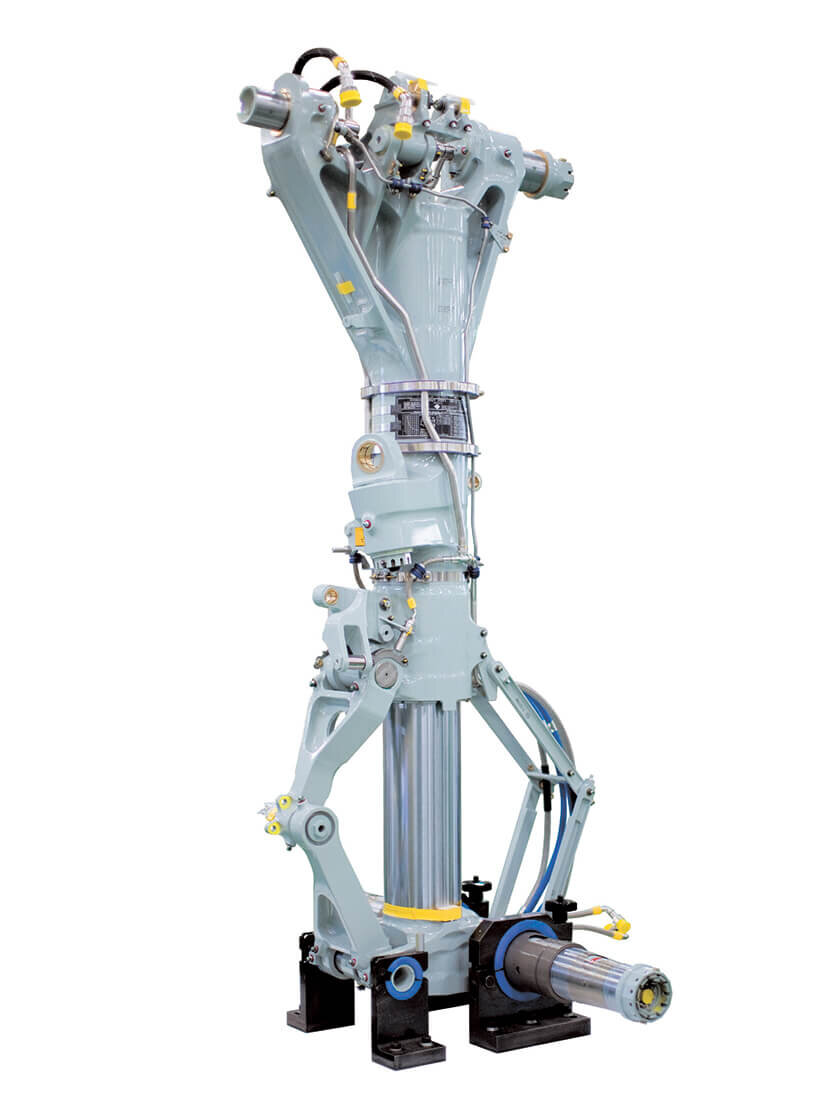

CRJ700/900/1000 main landing gear (impact absorption during landing)

Characteristics of landing gear

As for products for Ministry of Defense, approximately 80% of the aircraft currently owned by Ministry of Defense are equipped with our landing gear systems. For civil aircraft, our systems are used in aircraft of well-known aircraft manufacturers, both domestic and international. We have a particularly strong presence in the field of regional jets (medium-sized aircraft), capturing approximately 15% of the global market share. We are involved in almost all development of domestic aircraft. We have accumulated technical experience as an integrator of landing gear systems.

Our strength is our Precision processing technology for high-strength metal materials. This inimitable technology has earned us great expectations and trust, and we have been involved in the design, development, production technology, and manufacturing of landing gear for many years.

Furthermore, in order to reduce the environmental impact, various equipment is being electrified. Currently, we are working on joint research and development with Airbus S.A.S of France on an EHA (Electro-Hydrostatic Actuation) system for retracting and extending landing gear.

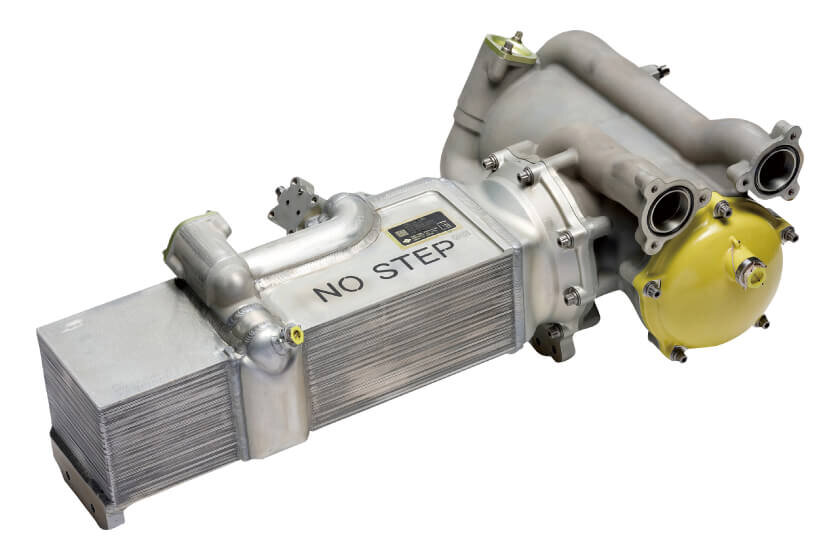

FOHE for Trent 1000® engine

Characteristics of Aerospace Thermal Management system

Since the 1980s, we have been supplying heat exchangers to Rolls-Royce plc, one of the three major aircraft engine manufacturers, for almost all of their engine series. In 2009, our performance with Rolls-Royce plc was recognized, and we were awarded the "Supplier of the Year" award.

We will develop new technologies and systems centered on thermal management technology and metal material joining technology, contributing to the high efficiency, small size and light weight of aircraft, as well as reducing air resistance, fuel efficiency and noise of aircraft engines.

The electrification of various aircraft equipment is increasing the amount of heat generated by various devices inside the engine. Meanwhile, the flow rate of fuel used as a coolant to dissipate the heat is decreasing as fuel efficiency improves. In other words, improving the cooling performance of thermal control systems has become an important technological challenge. Currently, we are working in collaboration with Rolls-Royce on research and development of a highly efficient, lightweight, and compact thermal control system for next-generation engines.

- Members speak out! Spilled Stories in the Aerospace Business

I feel the joy

of supporting flights around the world.Our strength is that we provide a consistent service from design to manufacturing to after-sales support. In the aviation industry, it is relatively rare to find a company that has design and manufacturing rights and can provide operational support while communicating directly with airlines around the world. I feel happy when I realize that my support is supporting flights around the world.

M.I Aerospace Second Sales Department Civil Aviation Sales Division

Industrial Equipment Business

We support industries around the world

with our unique technology.

We are applying the technology we have cultivated in Aerospace Heat Exchanger to energy and industrial equipment applications. Specifically, we develop and manufacture heat exchangers, LNG vaporizers, and hydraulic control equipment. Our heat exchangers range from low-temperature industrial heat exchangers used in industries such as petrochemicals, natural gas, steel, and semiconductors, to general-purpose industrial heat exchangers used in railcars and power equipment, as well as high-temperature heat exchangers used in fuel cells, cogeneration, and ultra-pure gas production. We boast a leading global market share in LNG (liquefied natural gas) vaporizers. As for hydraulic control equipment, we develop and manufacture hydraulic pumps used in high-precision injection molding machines, as well as hydraulic control valves and coolant equipment. All of these products are sold domestically and globally.

Main products and features

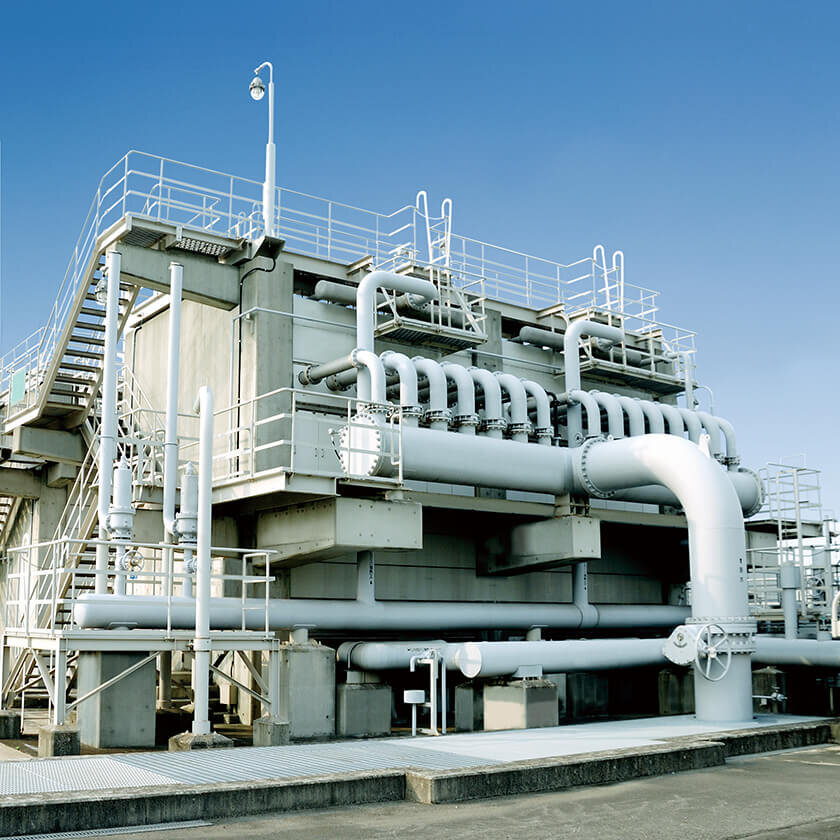

LNG Vaporizer

Air separation unit heat exchanger

Heat exchanger features

Since developing Aerospace Heat Exchanger using our proprietary Aluminum immersion brazing method, we have been supplying high-performance, compact heat exchangers to various energy fields in industry and society.

Since delivering the first open rack LNG vaporizer (ORV) in Japan, we have contributed to the creation of a global energy value chain with our advanced technological capabilities. Our low-temperature industrial heat exchangers, used in applications such as air separation units and petrochemical plants, are highly regarded as a top brand, occupying an extremely large share of the domestic market and establishing ourselves as a major player in overseas markets as well.

As a main supplier of inverter control element coolers for high-speed railways to various heavy electrical equipment manufacturers in Japan, we boast the top share in the domestic market for element coolers for Shinkansen trains.

As part of our efforts to create a sustainable society, we have begun developing and supplying stainless steel heat exchangers for hydrogen stations, with the aim of realizing a hydrogen society. These stainless steel heat exchangers use a diffusion bonding technology that differs from conventional brazing, and are compact and space-saving, allowing them to cool ultra-high pressure hydrogen.

As part of our efforts for the future, we have developed a heat exchanger for data center servers. It is a compact and lightweight element cooling device that can handle CPUs with high loads and high heat density. We are currently promoting sales of this product as one of our next-generation strategic products, including for use in power conditioners for renewable energy generation such as solar and wind power, in addition to data centers.

QS Pump

Coolant pump

Hydraulic control device features

After the war, at the beginning of the period of high economic growth, as domestic demand for hydraulic products surged, we introduced technology from a British hydraulic product manufacturer and, leveraging our experience in manufacturing hydraulic equipment for aircraft, we sell hydraulic pumps that are characterized by their energy-saving, low pulsation, and low noise for a variety of applications, including transportation and general industrial equipment.We established a joint venture in China with the Haitian Group the world's largest injection molding machine manufacturer, and are expanding our business based on this strong partnership.

We also handle coolant pumps, which are essential for machining. We offer a product series that can handle a wide range of pressures, which helps in manufacturing that requires advanced processing and shortens processing time. Our products are well known worldwide, and are affectionately known as "Sumitomo's pump" in Asia.

- Members speak out! Industrial Equipment Business

Anecdotes

A business that supports the foundation of Japan.

We manufacture heat exchangers that support social infrastructure, such as heat exchangers for large plants that support the semiconductor industry and element coolers installed on Shinkansen bullet trains.We also manufacture heat exchangers for natural gas and hydrogen stations, which have a low environmental impact, and will continue to support Japan's infrastructure business with products that meet social needs.

T.K Production Technology Group, Production Department - Heat Exchangers

ICT business

We are a leading company

in MEMS manufacturing.

We develop and manufacture MEMS and semiconductor manufacturing equipment. In 1995, we were the first in the world to bring to market silicon deep drilling equipment, which is essential for MEMS manufacturing. Recently, we have also been contributing to the production of gallium nitride high-speed ICs and filters for mobile devices in preparation for the use of IoT and big data in 5G communications and beyond.

We also utilize MEMS manufacturing equipment to develop high-precision sensors and other MEMS devices. We also provide ozone generators for use in fields such as water treatment and semiconductor manufacturing. We will continue to develop products that utilize the potential of ozone, with an eye toward expanding into fields such as medicine.

Main products and features

Silicon deep drilling equipment

Silicon oxide film sacrificial layer etching equipment

MEMS and semiconductor device characteristics

Our extensive lineup of MEMS and semiconductor manufacturing equipment is a distinctive feature. We can handle a wide range of needs, from user development and prototyping to mass production. Our flagship product, Precision deep silicon drilling equipment used in the 3D processing of MEMS and other electronic devices, together with our subsidiary SPP Technologies Co., Ltd. Co., Ltd., supplies 90% of global demand (according to our own research), making us the world's largest manufacturer of such equipment.

In addition, based on the technology cultivated in MEMS, we are also developing high-quality CVD (chemical vapor deposition) equipment and plasma etching equipment for the manufacture of LED and compound semiconductor devices. From March 2024, we will begin full-scale global sales expansion.

High-precision gyro

MEMS device characteristics

In 1999, our joint venture, Silicon Sensing Systems, began mass production of MEMS gyro sensors. Our track record spanning more than 20 years has earned us trust. Since our MEMS devices were adopted for applications such as automobile electronic stability control systems, we have received numerous inquiries from the high-precision market, and are known as the "world's most accurate MEMS gyro." Our devices are used in a variety of mobile attitude control systems and safety systems, including mineral resource mining, railway car bodies, GPS antennas, and satellite attitude control. We also operate a foundry business, handling the development and contract manufacturing of advanced MEMS devices for our customers.

We are also developing sensor application products that incorporate Precision' proprietary systems into Silicon Sensing Systems' gyro sensors.

General-purpose ozone generator

Ozone-added ultrapure water production equipment for the semiconductor and FPD industries

Ozone Generator Features

Ozone has a powerful oxidizing power, but at the same time, it decomposes back into oxygen, making it environmentally friendly. Ozone is an essential technology for water treatment and manufacturing processes in the public and industrial sectors. We provide advanced water treatment systems that can decompose and remove harmful, persistent substances that are suspected of being carcinogenic. We have a proven track record of delivering ozone to a wide range of applications, including water supply and sewage systems, swimming pools, aquariums, industrial water/wastewater, recycled water, and other wastewater treatment plants, as well as food and industrial product production processes and pulp and textile bleaching processes.

We provide high-concentration ozone generators and ozone-added ultrapure water production systems for various manufacturing processes, such as film formation and cleaning, for cutting-edge semiconductors, which are becoming increasingly miniaturized and highly integrated.

- Members talk about ICT business anecdotes

The possibilities are endless.

We manufacture piezoelectric thin films that boast the world's highest performance for MEMS applications. These are used in ultrasound probes for medical diagnosis and MEMS mirror components for automobiles. They are products that will support the foundation of the IoT society of the future. We also receive development requests from other well-known, super-major IT companies. Applications are only just expanding. This is a product and market that we look forward to seeing grow. RM MEMS Infinity Division, Second Development and Prototype Group