Products

Various heat exchangers in energy market

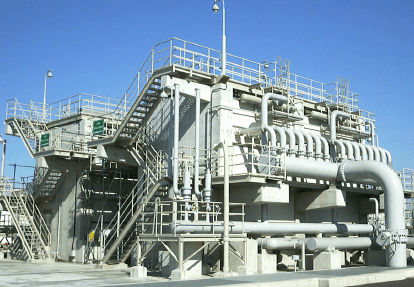

LNG vaporizer

As equipment for vaporizing LNG (Liquified Natural Gas). We deal with 2 types of vaporizer, that are,open rack type and submerged combustion type. For both vaporizer, we have large share in the world, and plentiful experiences.

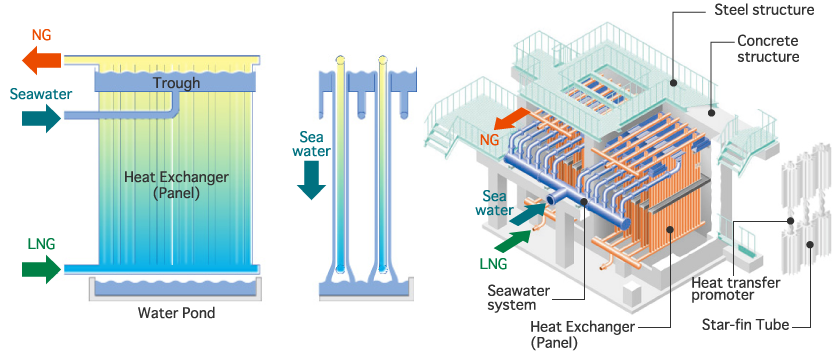

Open Rack LNG Vaporizer (ORV)

In the Open Rack Vaporizer, seawater flows on the surface of panels with many heat exchanger tubes (star-fin tubes) to vaporize the internal LNG. Seawater used as a heat source can reduce the operating cost, and the simple open-rack structure brings easy operation monitoring, maintenance, and inspection. This is the safest and the most reliable vaporizer of its kind. ORV (Open Rack Vaporizer) is a mainstream vaporizer for base-load operations throughout the world.

Main components

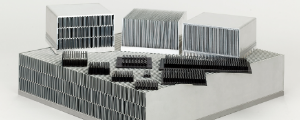

ORV is mainly composed of (1) Heat Exchanger, (2)Seawater system, (3)Support structure.

Among the componets, (3)Support structure is composed of steel structure and concrete structure.

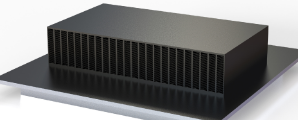

- 1Heat Exchanger (Panel)

- Lining up a number of Aluminum heat exchanger tube (called panel), flowing LNG inside the tubes, and LNG is to exchange heat with seawater that flows down outside of tubes and vaporized.

- 2Seawater system

- System for supplying seawater which works as heat source. It is consisted of seawater manifold, distribution pipe, and trough.

- 3Support structure

- Structure for supporting area for maintenance work, and apparatus itself.

Features

1HiPer V (Optimum design of ORV)

The heat transfer phenomenon is complicated in the LNG vaporizer, because the multi-component LNG vaporizes inside, while seawater freezes outside deteriorating heat transfer coefficient. The large star-fin of the heat exchanger tubes of the latest HiPer V, as well as optimization of the shapes of the internal/external fins and the heat transfer promoter, prevents the fin grooves from getting clogged by icing and greatly improves the vaporizing performance.

2Low Operation Cost

Seawater used as a heat source saves the operating cost and the quantity of seawater can be reduced by the optimum design of the HiPer V.

3High Reliability

All parts in contact with LNG are made of aluminum alloy with excellent strength for cryogenic use. The ORV panels are coated with an aluminum-zinc alloy to provide corrosion resistance against seawater. Aluminum-zinc alloy coating not only prevents direct contact between the base metal and seawater but also prevents corrosion of the base of metal as the sacrificial anode. The aluminum-zinc alloy clad tube (option) made by extrusion process has longer life than the thermal spray coating reducing the maintenance cost.

4Easy Operation

Quick start and operation under rapid load fluctuation within a range from 0 to 100% according to the change in demand are possible. The explosion-bonded dissimilar metal joint (transition joint) between the ORV panel and the LNG inlet piping prevents leakage due to a sudden temperature change and secures the safety.

5Flexible Design

ORV is comprised of panel blocks, and the number of tubes, panels and manifolds are flexible. According to the operating conditions (LNG load capacity and the flow rate and temperature of seawater) the installation space can be minimized.

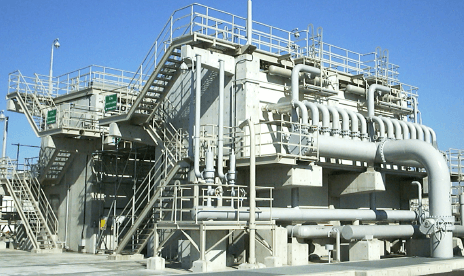

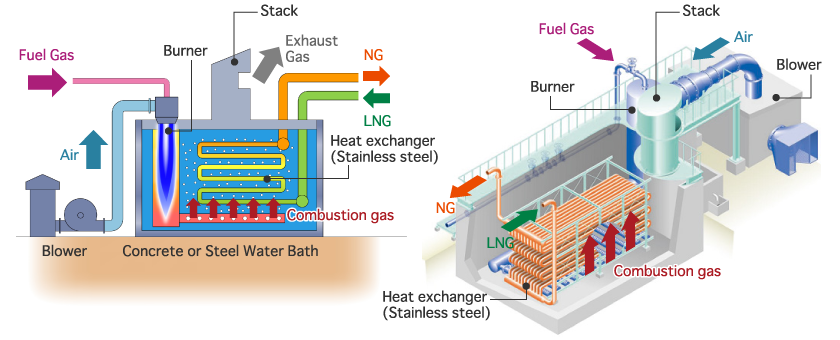

Submerged Combustion LNG Vaporizer (SCV)

In the Submerged Combustion LNG Vaporizer (SCV), hot water heated by the submerged combustion burner vaporizes the LNG in the stainless steel tube bundle. SCV is used for not only base load vaporization but also peak shaving or emergency operations. Due to large heat capacity of the water bath, SCV provides rapid response time for start-up, shut-down and rapid load fluctuation.

Main components

SCV is mainly composed of (1) Heat Exchanger, (2)Combustion system, (3)Control system, (4)Support structure.

- 1Heat exchanger

- Heat exchanger is composed of bundled stainless steel tubes. Flowing LNG inside the tubes, LNG is vaporized exchanging heat form warmed water by combustion gas.

- 2Combustion system

- System for warming water bath by combustion gas produced at burner, composed of blower, burner, downcomer, fuel gas piping, etc.

- 3Control system

- System for controlling start-up and shut-down.

- 4Support structure

- Structure for supporting area for maintenance work, water bath and apparatus itself.

Features

1Compact Design

Seawater channels, drainage channels, and other large facilities are unnecessary because seawater is not used, and the utility equipment construction cost can be reduced as a whole. Combustion gas is injected through the sparge pipe holes into the bath water creating frothing two-phase mixture. The two-phase frothing flow through the tube bundle efficiently scrubs the tube surface, ensuring very high heat transfer coefficient as well as a very compact design.

2High Thermal Efficiency

SCV can achieve very high thermal efficiency, approaching 100%,in HHV basis, due to low bath water / exhaust gas temperature.

3High Reliability

All parts in contact with LNG are made of stainless steel with excellent corrosion resistance and strength in cryogenic use. 304L and 316L low-carbon stainless steels that hardly cause stress corrosion or intergranular corrosion are used for the tube bundle. The simple structure permits easy maintenance.

4Easy Operation

Quick start-up and shut-down is possible, and the load can be changed rapidly from 10 to 100% to cope with the change in demand.

5Environmental Friendliness

Environmental friendly design has been adopted to ensure ultra low NOx and CO emission.