Products

Various heat exchangers in energy market

Diffusion Bonded

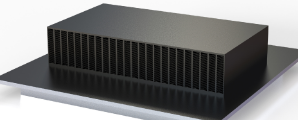

Micro Channel

Heat Exchanger

“DuraBlex®”

Heat exchanger which is made of flat plates with etched groove stacked, and bonded by diffusion phenomenon of metal. Due to structure with thick fins, this heat exchanger withstands more severe conditions than plate-fin heat exchangers. It is used for high pressure use like hydrogen station. And also expanding its use for condition of severe thermal cycle but requiring compactness, like LNG fueled vessel, LNG tanker, and FSRU (Floating Storage and Regasification Unit) .

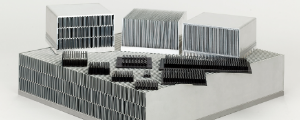

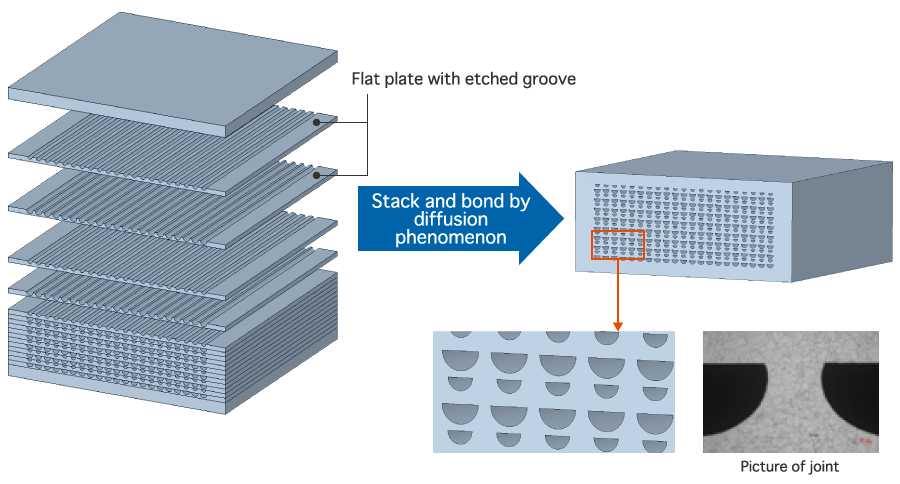

Structure

- Stainless steel flat plate with etched groove to be stacked, and bonded by diffusion phenomenon of metal.

- Metal texture in the bonded joint is completely blended, the joint can be regarded same as mother material.

Features

1Possible to use in high pressure, maximum design pressure is around 100 MPa.

Due to the tough structure than plate-fin heat exchanger, it is suitable for high pressure use which requires strength and durability.

2Compact and light weight, comparing to the other type of heat exchangers.

Similar to plate-fin type heat exchanger, due to the structure of etched flat plate and diffusion bonding, heat transfer surface is enlarged. So heat exchanger can be compact. Diffusion bonded micro channel heat exchanger covers conditions which is difficult to use plate-fin type.

3Material is SS 316L Hi-Ni with good Hydrogen resistance.

4Comply with ASME BPVC Sec. VIII Div. 1, European PED,

and Japanese pressure vessel code.

Reliability test result

Tensile test

Ductile rupture

Satisfy Stipulated value in code

(Tensile strength, 0.2% proof strength, elongation)

Water burst test

No leakage by 4 times of design pressure (90MPaG)

Cyclic pressure test

100,000 cycles by water pressure (1-90 MPaG)

Hydrogen brittleness check

No influence of pressured Hydrogen by Slow Strain Rate tensile Test (SSRT)

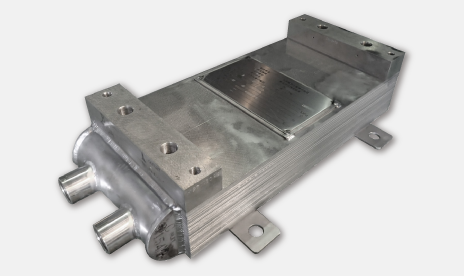

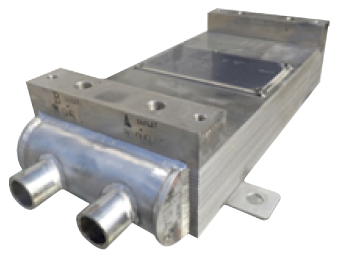

Application example for Hydrogen compressor of Hydrogen station

- Heat exchanger for compressor became 1/50 smaller by volume than before, by structure of etched flat plate and diffusion bonding.

- Material is SS 316L Hi-Ni with good Hydrogen resistance

After cooler for hydrogen compressor

Design pressure: 98MPa

Design temperature: 150 degC

Dimensions: 480×125×230mm

Conventional product

(double-pipe exchanger)

Micro channel

heat exchanger