Products

Various heat exchangers in energy market

Plate-Fin Heat Exchanger,

"SUMALEX®"

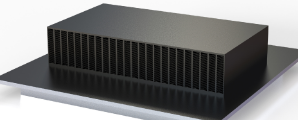

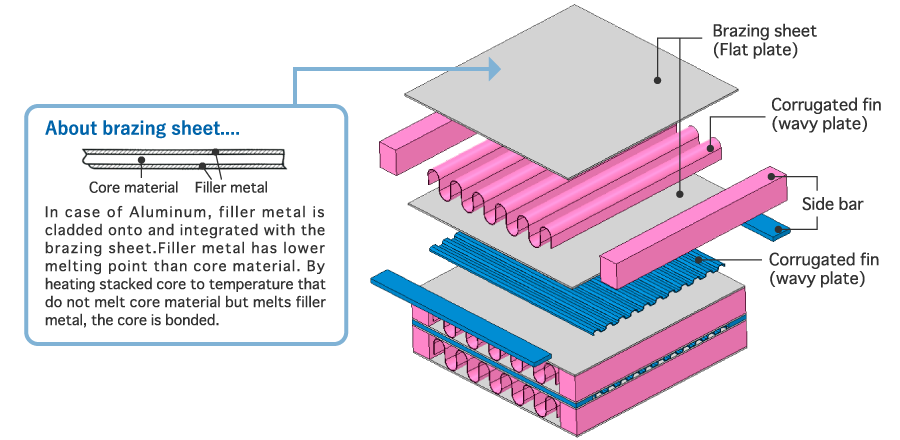

Our heat exchangers composes of corrugated fin and separation plate which are stacked and brazed. Comparing to the other type of heat exchangers, by enlarged heat transfer area , this type of heat exchanger becomes more compact and lighter. We can produce from large to small heat exchanger, and take flexible material choices, such as aluminum alloy, and stainless steel etc.

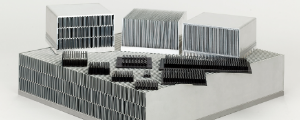

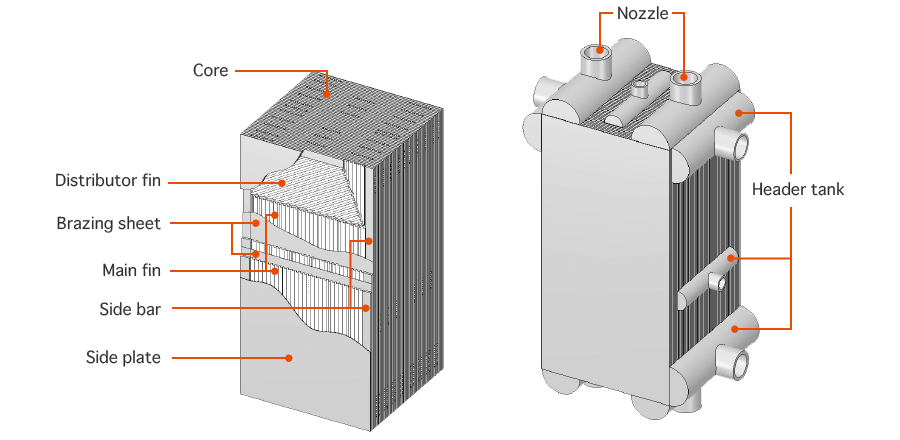

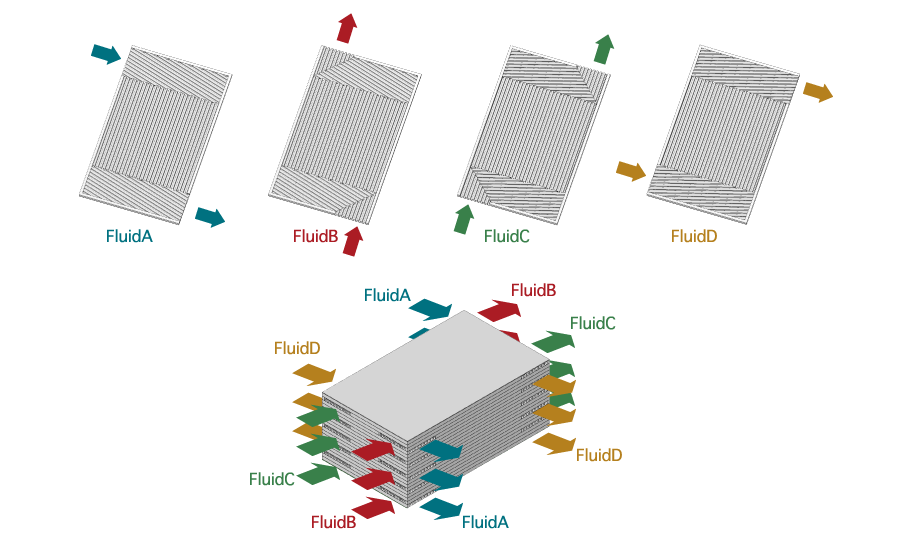

Structure

SPP's plate-fin heat exchanger "SUMALEX®" is made by stacking brazing sheet (flat plate) and corrugated fin (wavy plate). Each layer is individual passage.

Basic Structure

Product

Structure

Features

Plate-fin heat exchanger "SUMALEX®" has the following features;

1Light weight, Compact, and High thermal performance, comparing to the other type of heat exchangers.

Comparing to the other type of heat exchangers, if plate-fin type is applied, your heat exchanger can achieve compact and light weight in general, because heat transfer area is enlarged and heat transfer area per volume becomes large. Especially, in case of gas-gas heat exchange process, heat exchanger which is designed by enlarged heat transfer area becomes significantly compact and light weight.

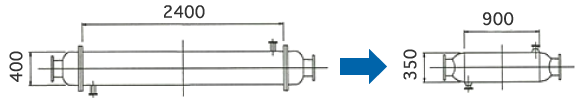

Model case: Comparison between "Shell & Tube" and "Plate-fin"

In comparison with Shell & Tube heat exchangers, the following benefits are expected for our Plate-fin heat exchangers;

- Smaller installation space.

- Simplification of support structure for heat exchanger

- Reduction in power consumption of compressor

| Shell & Tube | Shell & Tube | |

|---|---|---|

| Gas outlet temperature | 40℃ (Cooling water 32℃) |

34℃ (Cooling water 32℃) |

| Main unit dimension | 400Ø×2400 | 350×440×900 |

| Main unit volume | 0.30m³ | 0.14m³ |

- Temperature

difference : 2 ℃ - Running cost

improvement: 1% - Heat Exchanger volume

reduction:60%

2Best selection from various fin type.

For accommodating various customer requests, we assort about 300 kinds of corrugated fin, and offer most suitable selection for customer specification.

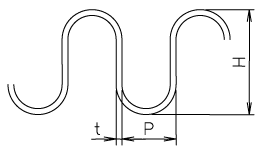

Fin shape

Plain type

Perforated type

Herringbone type

Louvered type

Serrated type

Fin dimension

| Min. | Max. | |

|---|---|---|

| Height H | 2mm | 25mm |

| Pitch P | 0.9mm | 8.5mm |

| Thickness t | 0.1mm | 0.6mm |

3Multi fluid heat exchange

Due to structure of plate-fin type, multi fluid heat exchange is possible. You can reduce piping and installation space. (Up to 15 fluid possible)

Passage arrangement - 4 fluid counter flow

4Superior air-tightness / durability

Corrugated fins are all brazed with brazing sheets, and configure integrated structure. They are not only for enlarging heat transfer area, but for withstanding high internal pressure, and provide superior durability. Production with this our original brazing technology and argon-arc-welding provides sound mechanical reliability and air-tightness.

5Quality, Reliability

"SUMALEX®" are widely used in the world. We have many experiences for applying many kinds of international / local codes. Also, our technology is internationally verified by various quality certifications.

Applicable codes

- - ASME BPVC Sec. VIII

- - European PED

- - EN 15085

- - Japanese pressure vessel codes

- - Membership of ALPEMA (Brazed Aluminum Plate-Fin Heat Exchanger Manufacturer's Association)

- - Codes of ship classification society

etc.

Quality certifications

- - ISO 9001

- - ASME (U Certification Mark)

- - NBIC (R-stamp)

- - Korean MA (Manufacture Approval)

- - ClassNK (Pressure Vessels, groupe 1)

etc.

Worldwide track records

- - Asian countries, including Japan, Korea, India, Thai, Malaysia, Singapore

- - North, Central, South America, including Canada, USA, Brazil

- - West and East Europe, including UK, France, Spain, Germany, Poland

- - CIS Counties, including Russia, Turkmenistan

- - Middle East, Africa

etc.

6Variety of materials selection

Depending on fluids or the other conditions, we can propose appropriate material, not only aluminum alloy, but also stainless steel, nickel alloy, and titanium alloy.

Example for use

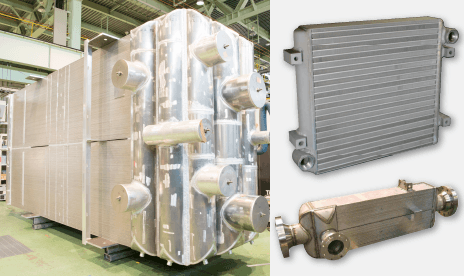

Plate-fin heat exchanger for air separation

(Aluminum alloy)

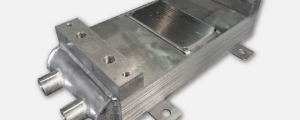

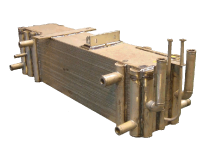

Oil cooler for industrial machine

(Aluminum alloy)

Oil cooler for high speed train

(Aluminum alloy)

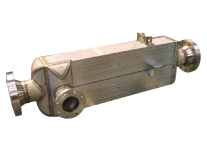

Heat exchanger for fuel cell

(Stainless steel)

9 fluid Heat exchanger for plant

(Stainless steel)

High pressure

heat exchanger for plant

(Stainless steel)

Gas turbine recuperator

(Stainless steel)