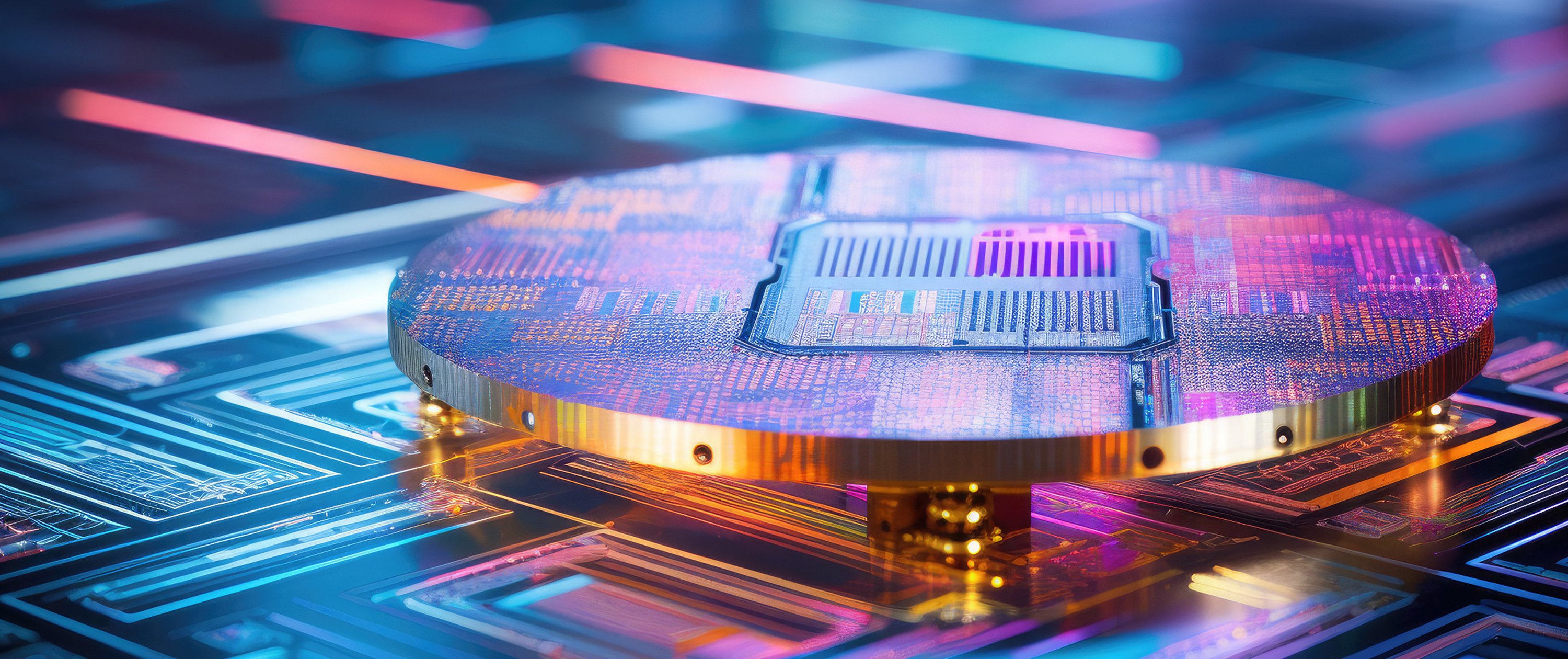

Si DRIE processing equipment

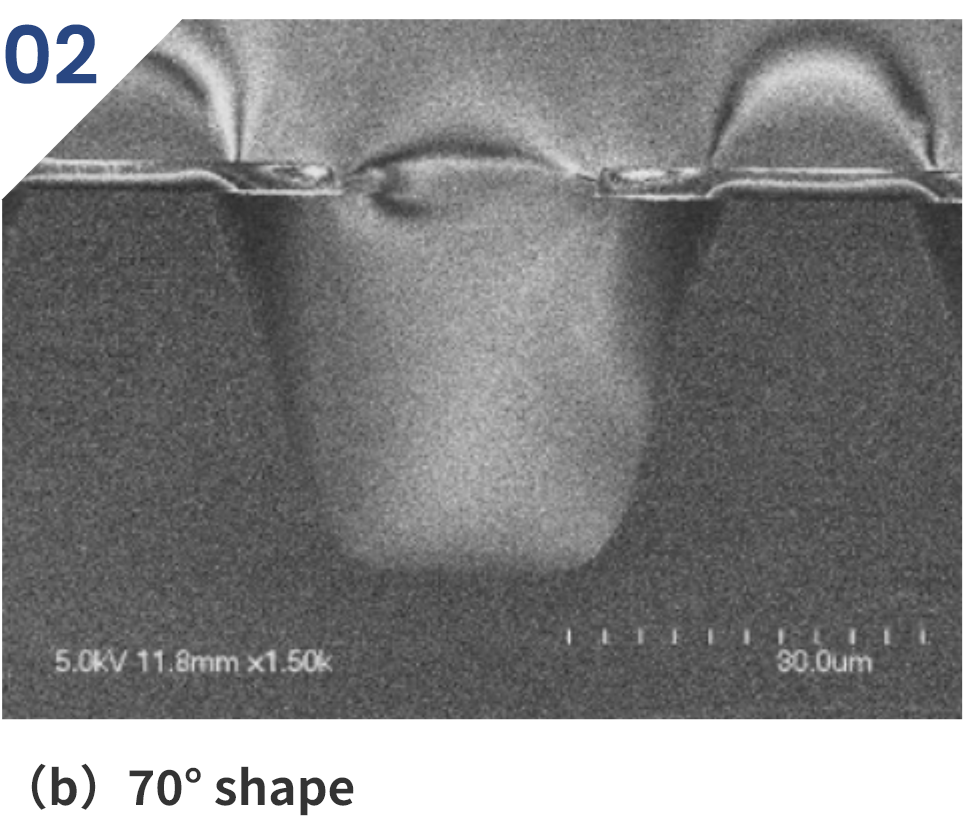

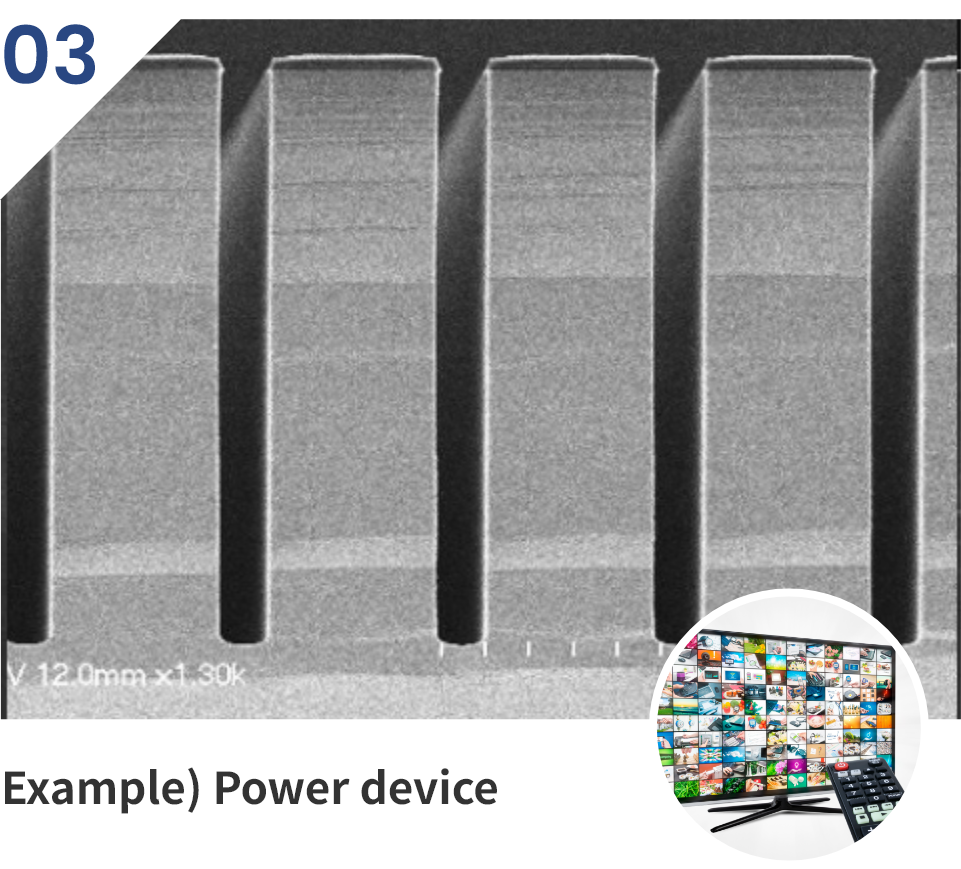

Deep Si etching

Our company launched the world's first practical Si deep excavation equipment in 2005.

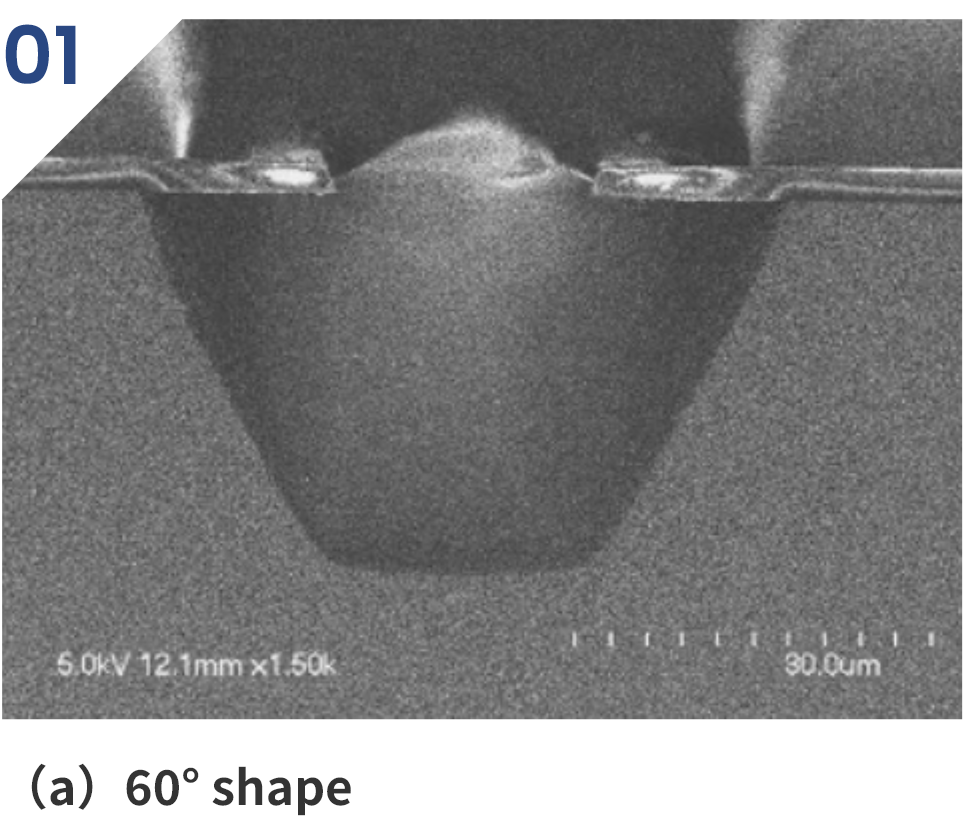

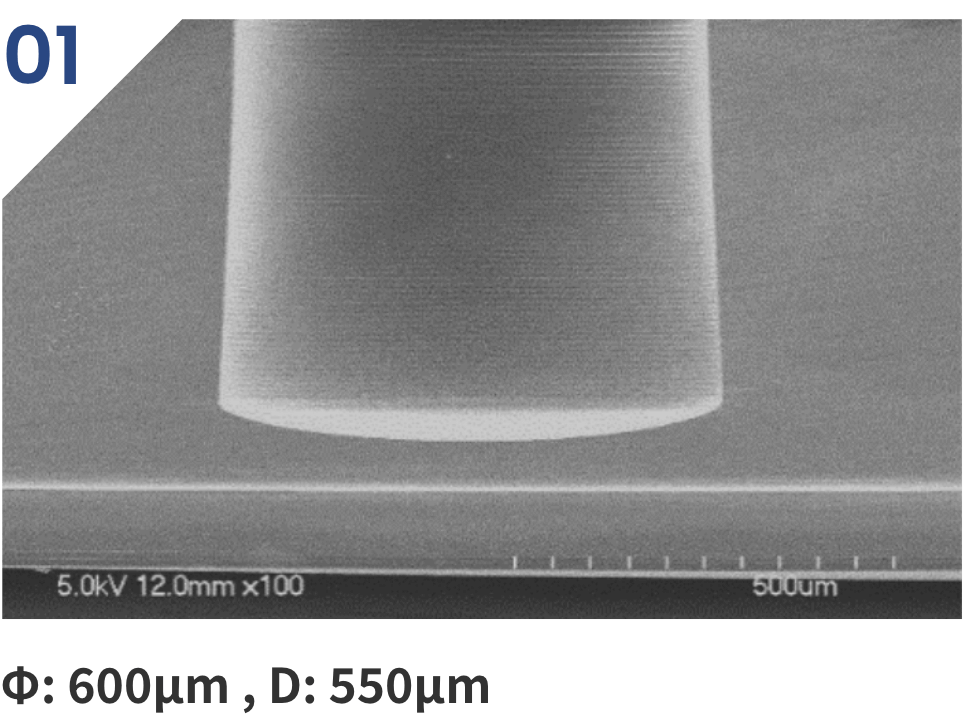

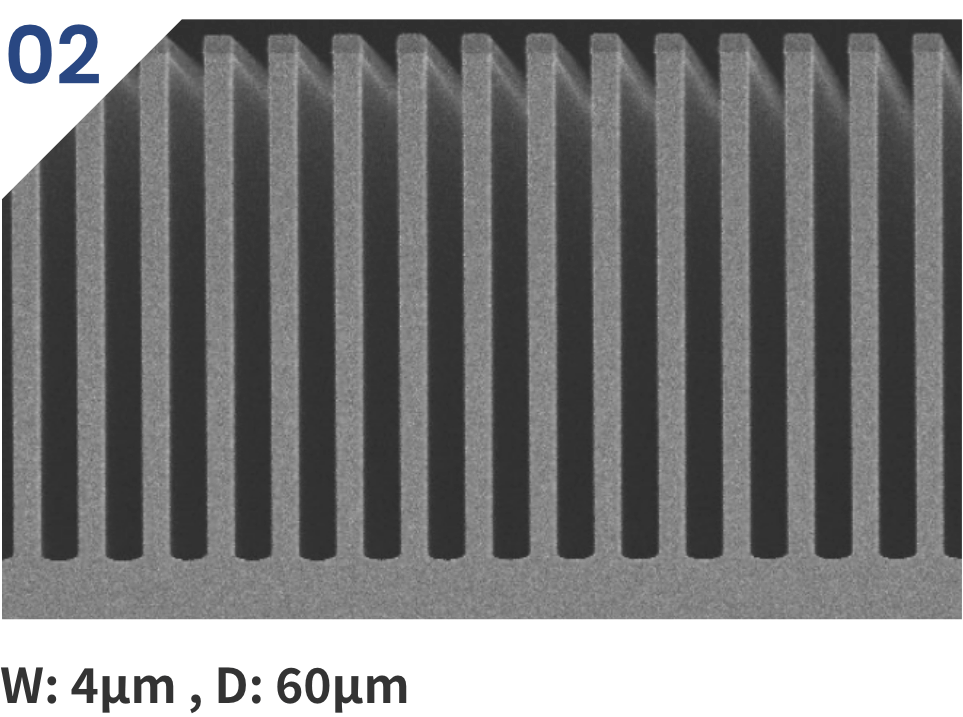

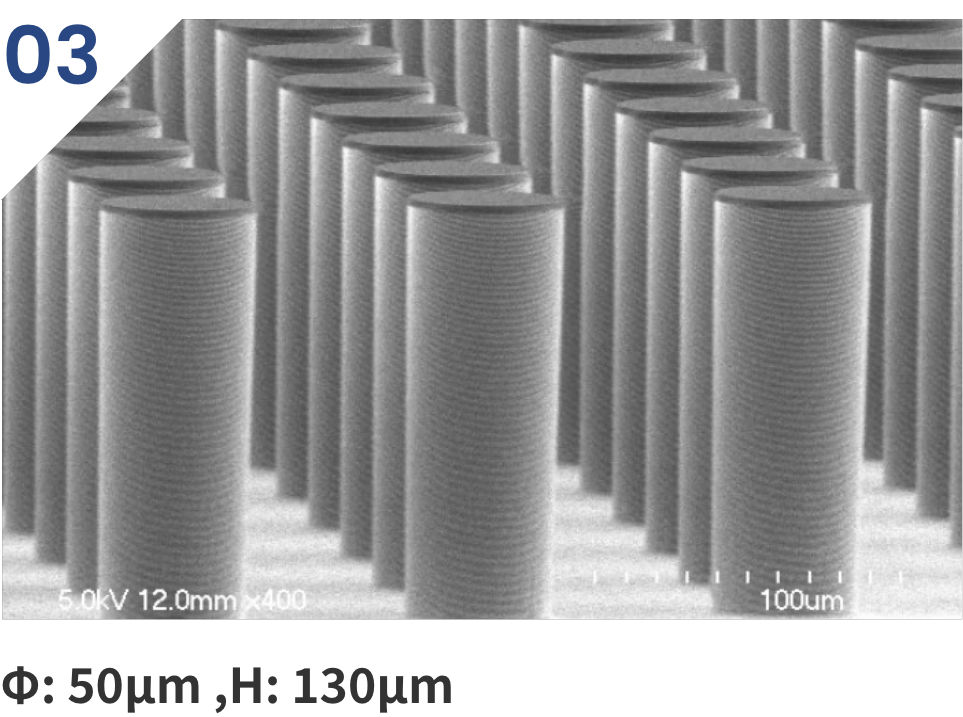

We have the technology to provide highly accurate and difficult etching.

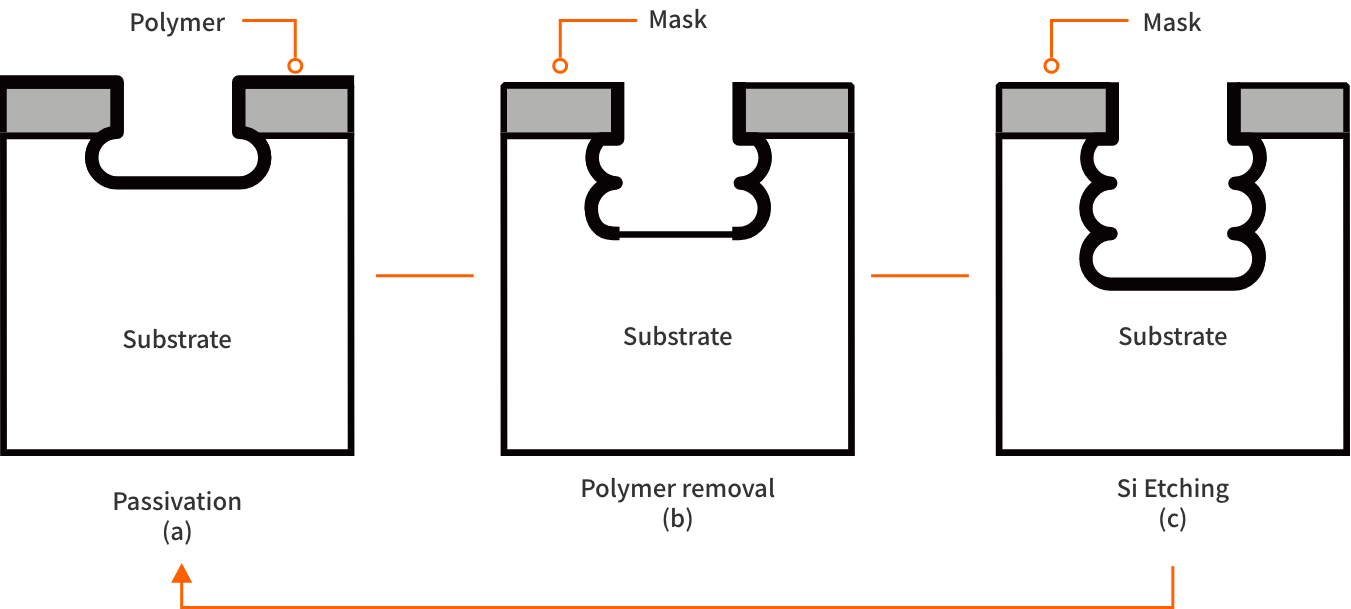

Mechanism of Si deep processing

(Si DRIE: "Bosch-Process")

The Bosch process "Bosch-Process" was developed in 1992 by Robert Bosch GmbH in Germany.

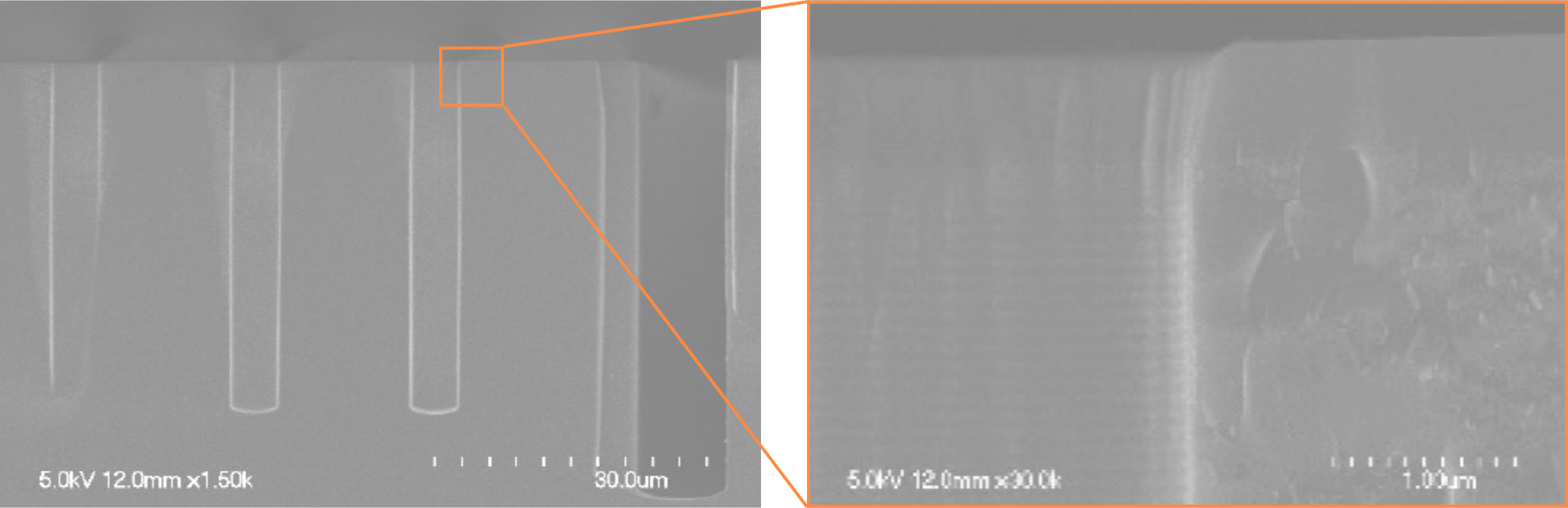

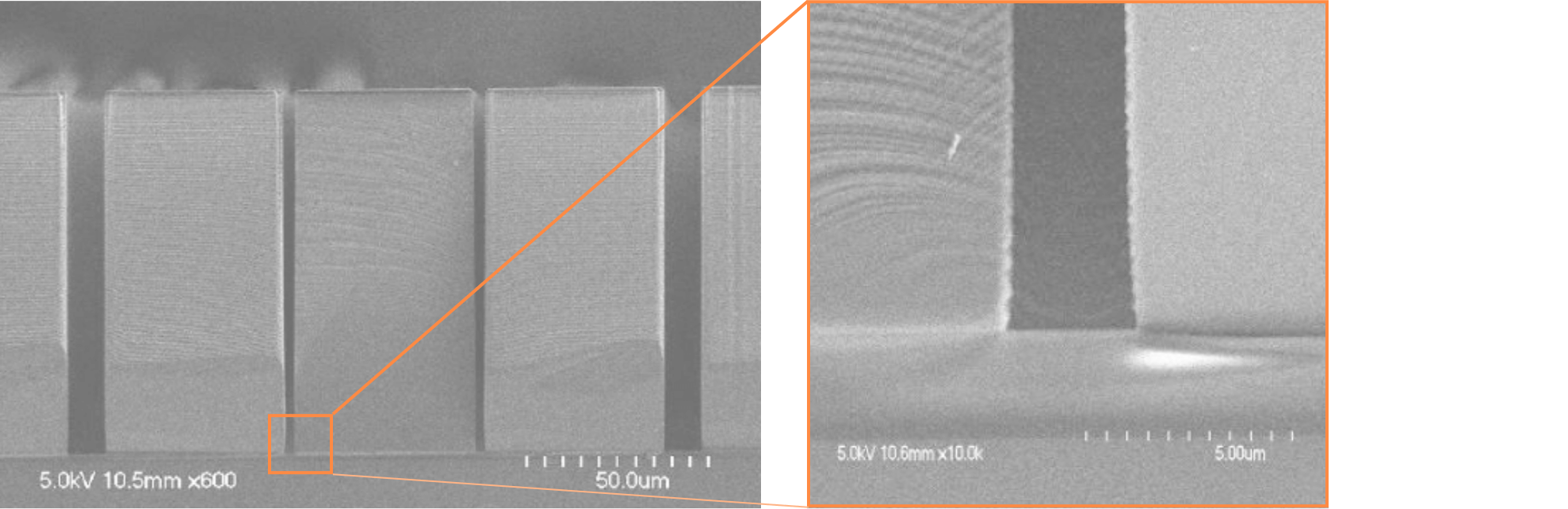

This is a switching etching method that repeatedly performs etching and passivation (forming a sidewall protective film).

We use various equipment from our group company SPP Technologies.

Using advanced technology, we can handle equipment with improved processing accuracy and productivity for various purposes from research prototyping to mass production.

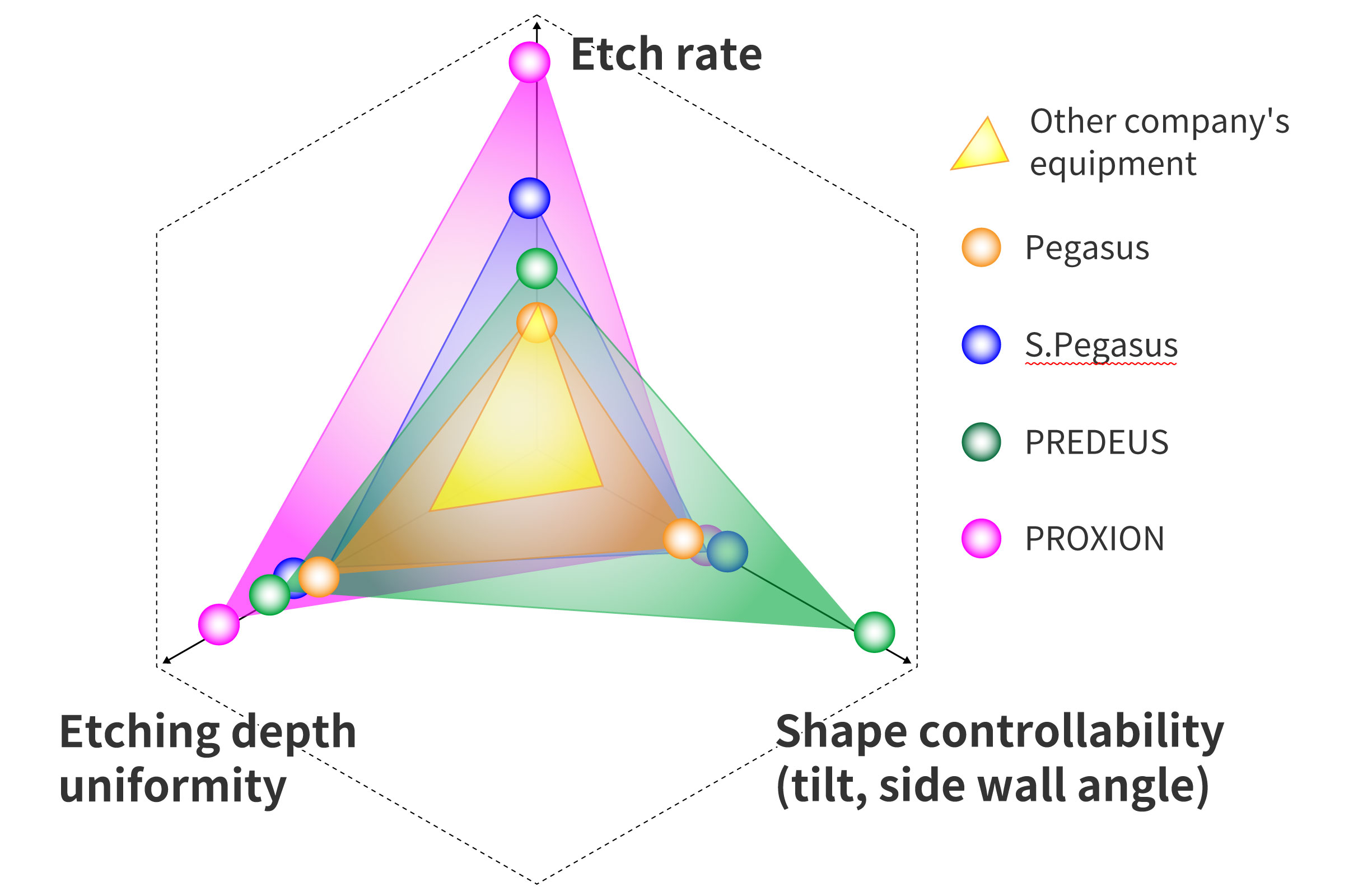

Evolution of Si DRIE process

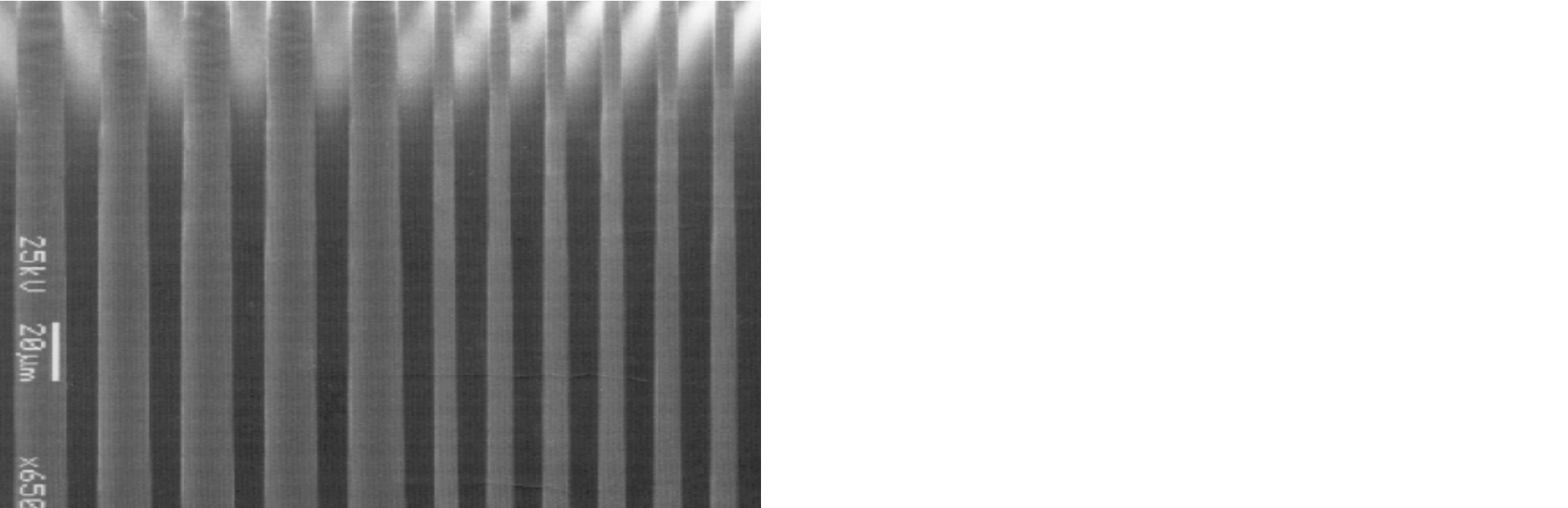

Etch rates have been significantly improved by improving the functionality of our in-house developed equipment.

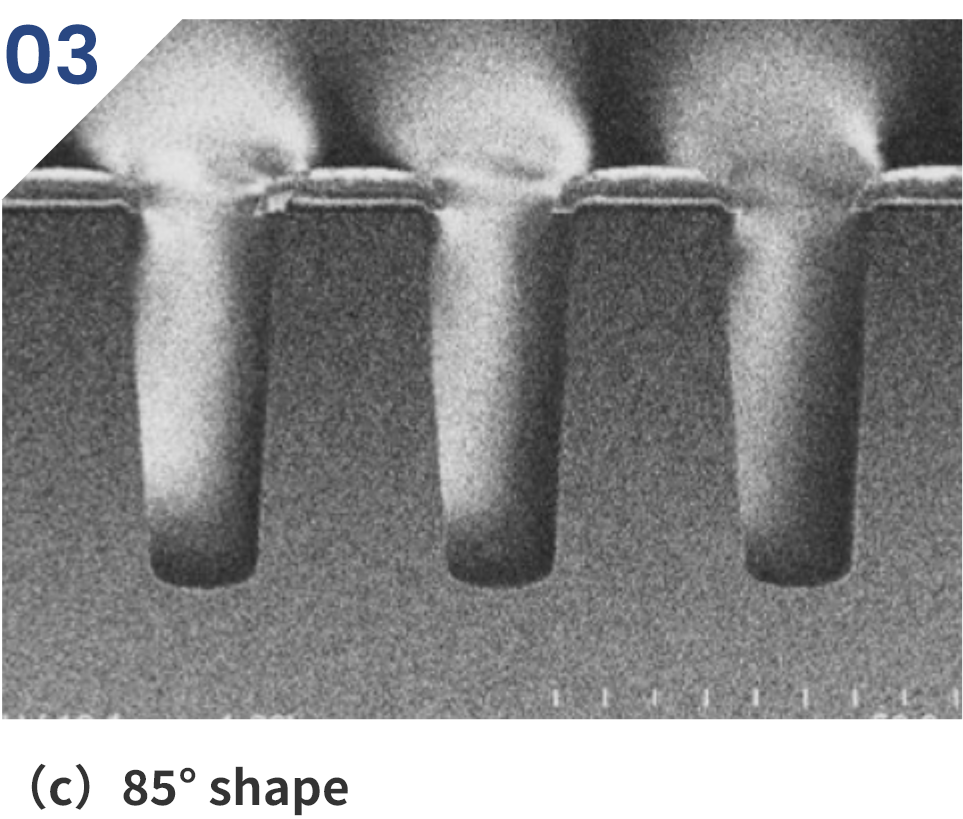

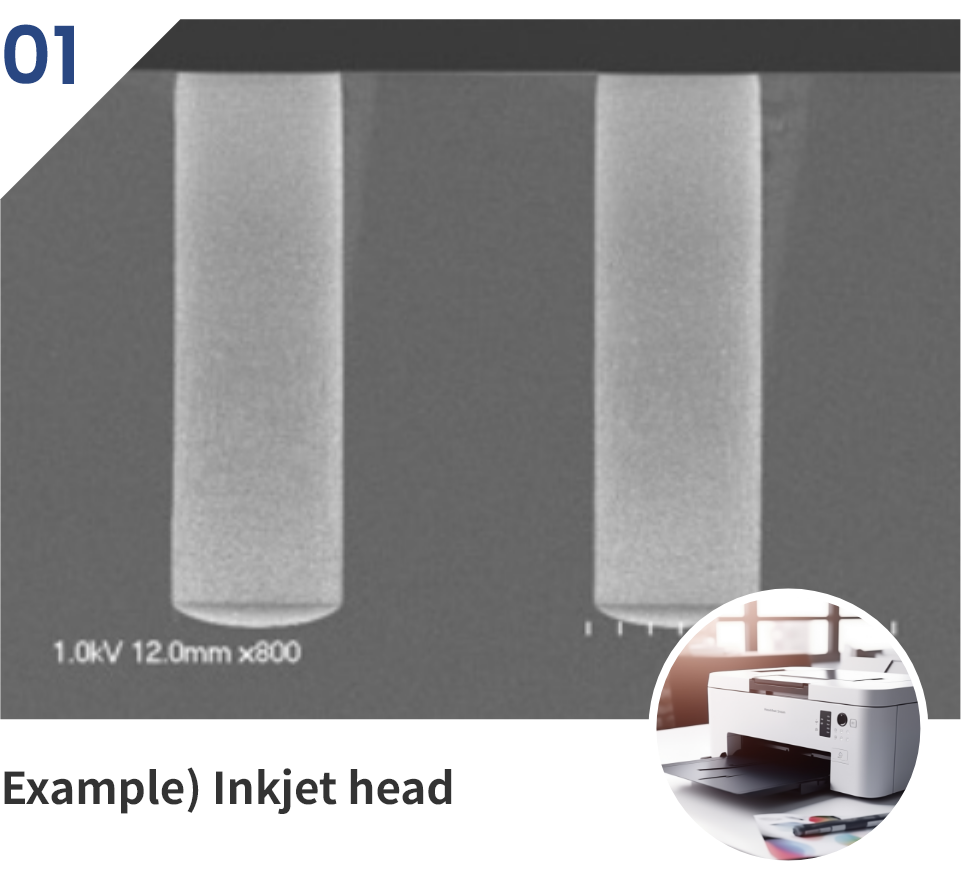

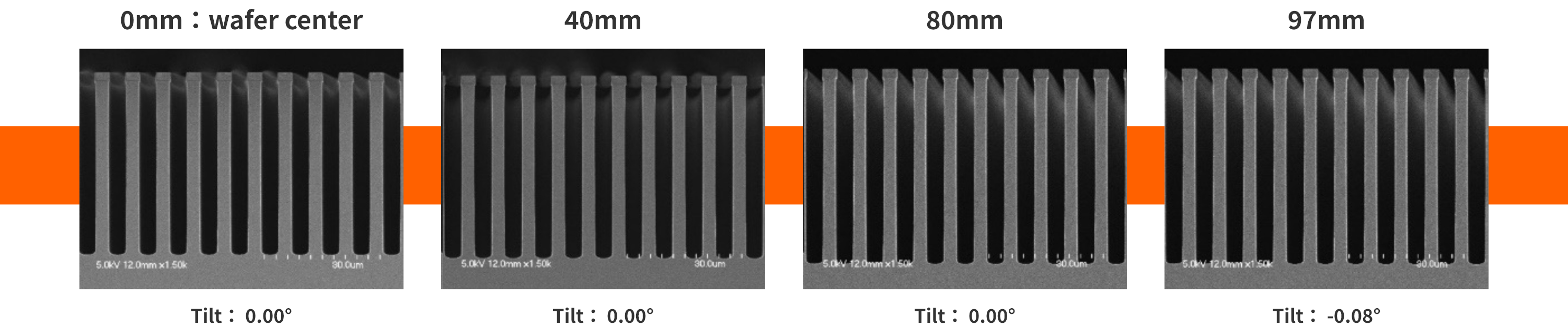

The shape controllability of the in-house developed equipment has been improved, and stable shapes can be reproduced even during deep etching.

Stable reproduction of tilt angles of 0.1° or less up to 3mm edge of 200mm wafer