Energy-saving Proposal for PumpsEnergy saving

Proposal for energy conservation and CO₂ reduction using coolant pumps

Under the Global Warming Countermeasures Promotion Act,

- Factory managers who are having trouble achieving their goals

- Those who are engaged in energy conservation activities at their company

We will propose to

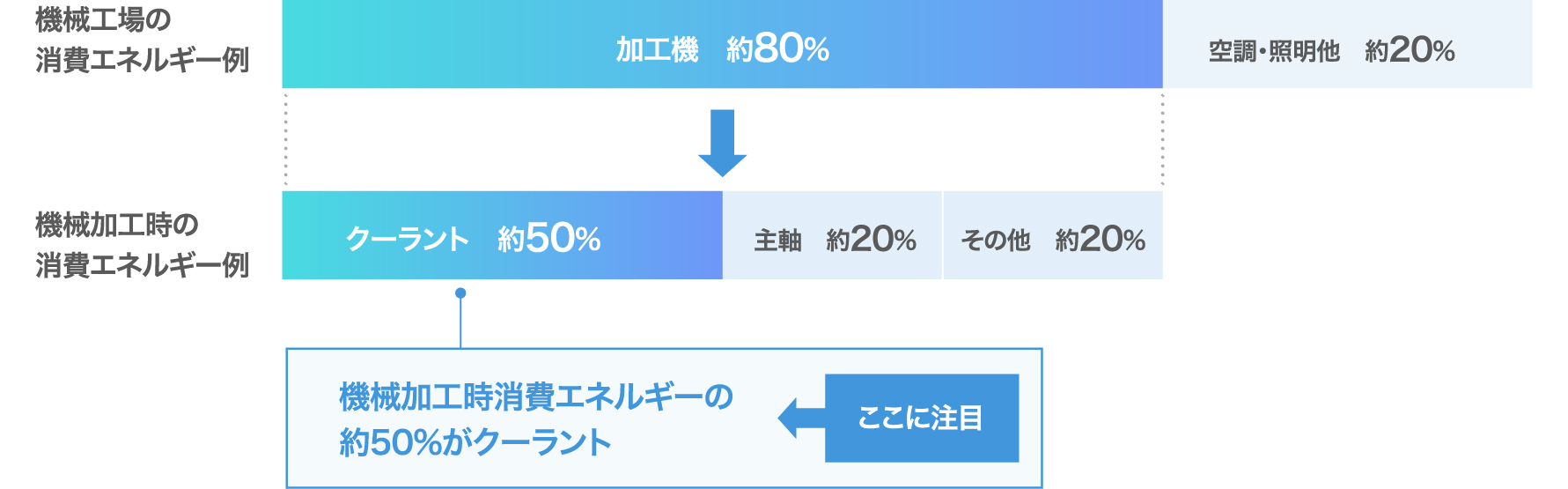

Did you know? Key points for saving energy in factories

Energy consumption ratio for machining (in the case of an automobile manufacturer)

Proposal 1: Energy-saving operation through inverter control

When combined with an inverter, it achieves approximately 50% energy savings (compared to our previous model).

Proposal 2: High-efficiency pumps save energy just by replacing them

The E3P uses an internal gear system, making it 30% more energy efficient (compared to our company's own products) than other companies' impeller-type pumps.

Replacing your existing pump will save 30% in energy.

| Fin code | Pressure | Motor Capacity | Energy saving rate |

|---|---|---|---|

| E3P (E3P-25-2.2) | 2MPa | 2.2kW | Approximately 30% |

| Other companies' impeller pumps | 2MPa | 3kW |

*Depending on the specifications, a motor one size smaller can be used.