Coolant pump Products

- Coolant pump

- High-pressure coolant pump CX

Coolant pump

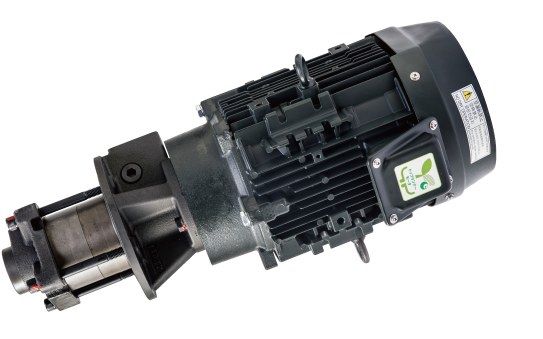

High-pressure coolant pump CX

Features

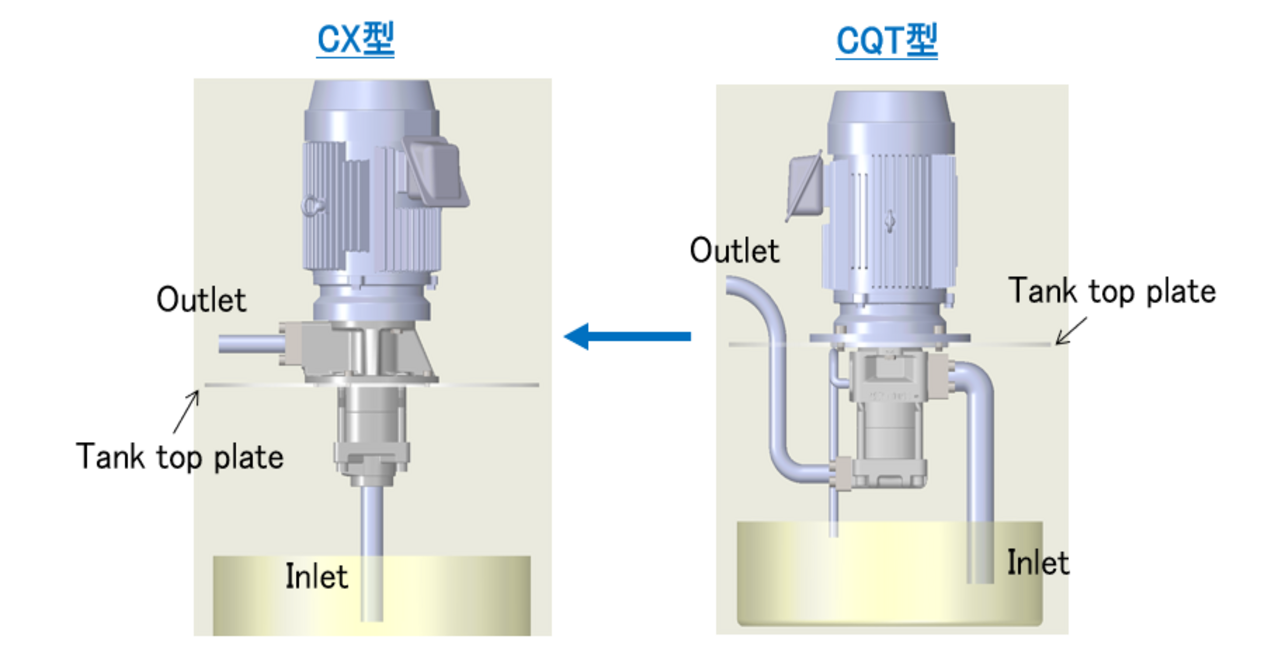

Piping labor: Cost reduction

- The position of the suction and discharge ports has been changed to significantly improve workability compared to previous models.

- The suction does not require a piping flange, and the piping connection method is an RC screw.

Reduced running costs

- Energy-saving operation is possible with inverter control.

- When combined with our inverter, pressure pickup is not required.

(It can also be operated with an existing inverter.) - The durability of the pump has been improved by using ceramic materials in part of the pump.

Improved maintenance performance

- Emergency response is possible. As with the E3P, customers can replace the gear housing set themselves.

- No external drain piping is required.

- We also sell the gear housing set only.

Energy saving

- Energy-saving operation is also possible with inverter control.

Compliant with overseas motor standards

- We currently provide services in a wide range of countries, including the US, EU, China, and Southeast Asia.

Relief built-in also available

*This is an optional specification.

By changing the piping structure, installation and replacement work hours have been significantly reduced.

Specification

| Maximum operating pressure/discharge flow rate (L/min) |

2.0MPa | 3.5MPa | 7.0MPa | 10MPa | |||||

|---|---|---|---|---|---|---|---|---|---|

| 50Hz | 60Hz | ||||||||

| 6 | 10 | ー | CX32 CQTM 32 |

-10 | CX33 CQTM 33 |

-10 | CX34 CQTM 34 |

-10 | |

| 10 | 14 | -12.5 | -12.5 | -12.5 | |||||

| 13 | 18 | -16 | -16 | -16 | |||||

| 17 | 25 | ー | CX42 CQTM 42 |

-20 | CX43 CQTM 43 |

-20 | CX44 CQTM 44 |

-20 | |

| 25 | 32 | -25 | -25 | -25 | |||||

| 32 | 43 | -31.5 | -31.5 | -31.5 | |||||

| 38 | 49 | ー | CQTM 52 |

-40 | CQTM 53 |

-40 | CQTM 54 |

-40 | |

| 53 | 68 | -50 | -50 | -50 | |||||

| 71 | 89 | -63 | -63 | -63 | |||||

| 84 | 107 | CQTM 51 |

-80 | CQTM 62 |

-80 | CQTM 63 |

-80 | CQTM 64 |

-80 |

| 112 | 141 | -100 | -100 | -100 | -100 | ||||

| 144 | 180 | -125 | -125 | -125 | -125 | ||||

| 193 | 235 | CQTM 61 |

-160 | ー | ー | ー | |||

| 248 | ー | -200 | |||||||