- Top page

- > Business introduction

- > Heat exchanger

Heat exchanger

Various heat exchangers for various worldwide industries

Since developing Aerospace Heat Exchanger using our proprietary Aluminum immersion brazing method, Sumitomo Precision Products has supplied high-performance, compact heat exchangers to various energy fields in industry and society. We have earned unwavering trust as a world-leading manufacturer in the fields of large-scale low-temperature industrial heat exchangers and LNG vaporizers.

- What is a "heat exchanger"?

- A device that efficiently transfers heat from a high-temperature object to a low-temperature object, generally handling fluids such as liquids and gases. Used for heating and cooling purposes, it is used in the heating and cooling processes of objects in gas and chemical production plants, and to cool cooling water and lubricating oil in various transportation equipment, facilities, electronic devices, and machinery.

Strengths of the Heat Exchanger Division

- High-performance, compact and lightweight plate-fin heat exchanger

- Stainless steel and titanium heat exchangers that can withstand harsh environments

- LNG vaporizers boasting the world's largest delivery record

- Compliant with a wide range of domestic and international manufacturing regulations

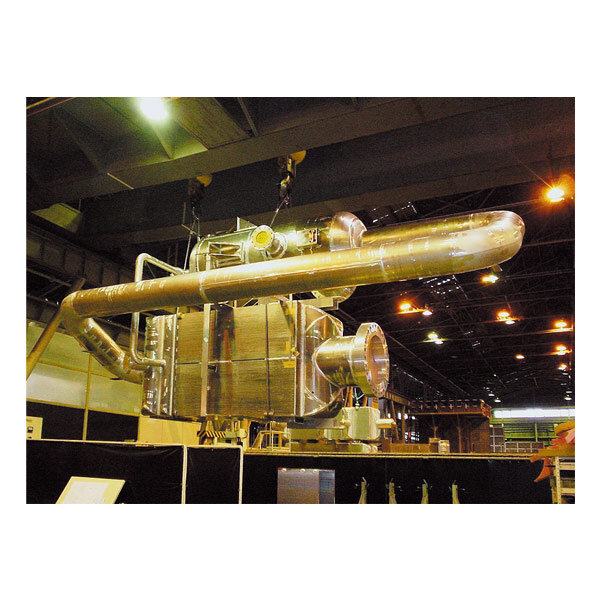

Low temperature industrial heat exchanger

Our large-scale heat exchangers are used in a wide range of low-temperature industrial applications, including petrochemicals, natural gas, air separation, steel, and semiconductors. These high-performance, lightweight, and compact plate-fin type heat exchangers are our main products and are used in a variety of industrial fields around the world.

This plate-fin heat exchanger, known as "Smarex," is now highly regarded as a top global brand.

- Petrochemical Plant

- Air separation unit heat exchanger

- Heat exchangers for petrochemical plants

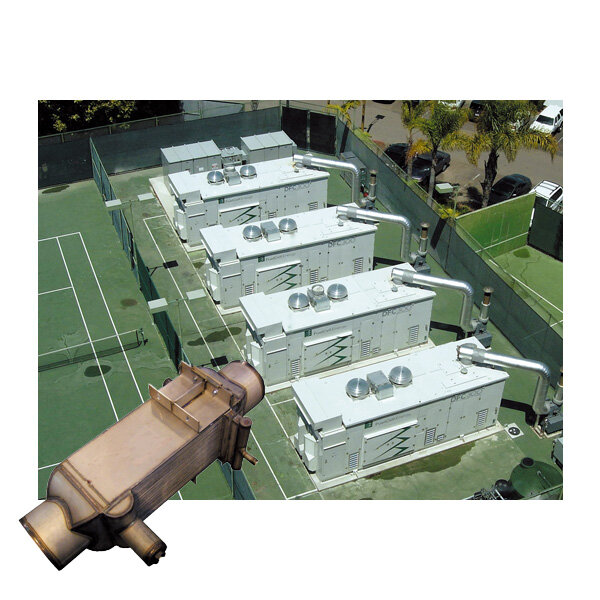

High temperature heat exchanger

In response to the need for highly efficient, compact heat exchangers that can be used in high-temperature and corrosive environments, we also manufacture stainless steel plate-fin heat exchangers. These are used in fields that require high durability, such as fuel cells, cogeneration, ultra-high-purity gas production equipment, and regenerators for gas turbines used in power generation. We also offer titanium plate-fin heat exchangers for use in severely corrosive environments such as seawater.

To meet advanced specifications, we offer a range of products with excellent functionality and structure, and are expanding the range of applications to include fields with higher temperatures and more severe operating conditions.

- Stainless steel heat exchanger for fuel cells

[Photo courtesy of FCE]

- Stainless steel heat exchanger for fuel cells

- Gas turbine regenerator

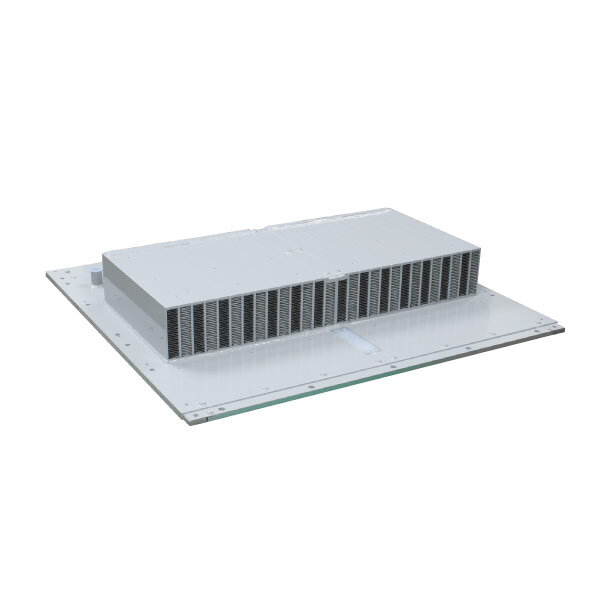

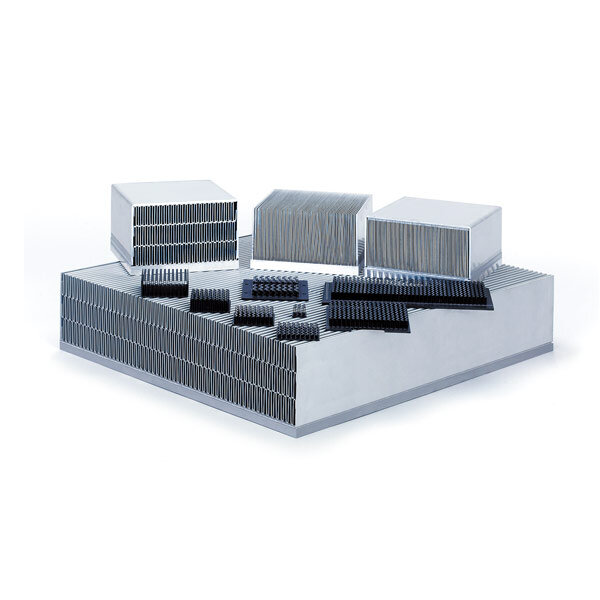

General industrial heat exchangers

We supply lightweight, highly reliable plate-fin heat exchangers to the fields of railway vehicles, including the Shinkansen, power equipment, various industrial machinery, and electronic equipment, which are used in harsh environments.Our product range covers a wide range, including transformer insulating oil coolers, power element coolers, and lubricating and hydraulic oil coolers.

- N700 series Nozomi

- Stationary transformer insulating oil cooler

- Oil cooler for industrial machine

- Shinkansen oil cooler

- Shinkansen element cooler

- Heat sink

LNG Vaporizer

Natural gas has become an essential energy source for industry and society. Natural gas is cooled to ultra-low temperatures and transported to remote locations by tanker as a liquid, known as LNG (liquefied natural gas). However, to be used as fuel, it must be converted back into a gas.

Sumitomo Precision developed heat exchanger technology and was the first manufacturer in Japan to develop LNG vaporizers. Today, as a leading global manufacturer, we supply LNG vaporizers to LNG receiving terminals not only in Japan but around the world.

- Submerged Combustion LNG Vaporizer (SCV)

- LNG receiving terminal

- Open Rack LNG Vaporizer