- Top page

- > Business introduction

- > MEMS and semiconductor manufacturing equipment

MEMS and Semiconductor Manufacturing Equipment Business

Leaping into the future of microtechnology

As a leading company in deep silicon processing equipment and silicon oxide sacrificial layer etching equipment, which are essential for MEMS manufacturing, Sumitomo Precision Products works with its partner companies to provide a range of process equipment that can offer a variety of solutions, contributing to the development of MEMS technology.

- What is "MEMS (Micro Electro Mechanical Systems)"?

-

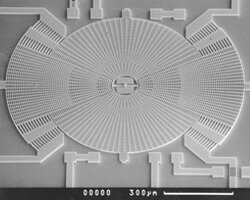

MEMS sensor (provided by Robert Bosch GmbH)

MEMS sensor (provided by Robert Bosch GmbH)By applying three-dimensional processing to wafers such as SOI or silicon at the micro level, devices that not only have circuits on the substrate but also mechanically moving structures are created, and are installed in familiar electronic devices.

Research and development is being conducted in a variety of fields, including automotive sensors for airbags, nozzle heads for inkjet printers, high-frequency devices and camera modules for mobile devices such as smartphones, and more.

Strengths of the MEMS and Semiconductor Equipment Division

- MEMS silicon deep drilling equipment boasts a 90% market share

- World's highest level of etch rate, high mask selectivity, and high aspect ratio processing are possible

- A wide range of semiconductor and MEMS manufacturing equipment available, from prototyping to mass production

Silicon deep drilling equipment

This is the de facto standard for silicon deep etching equipment for MEMS. We offer a wide range of equipment to suit various applications, from research prototype SRE machines to mass production standard Pegasus machines, and even Predeus machines with improved processing accuracy and productivity.

Equipped with hardware modules and process software that maximize the outstanding performance of the world's highest etch rate, high mask selectivity, and high aspect ratio processing, it is used for a variety of applications, including processing gyro sensors and accelerometers.

- Silicon deep drilling equipment

CPX ASE-Proxion

- Silicon deep drilling equipment

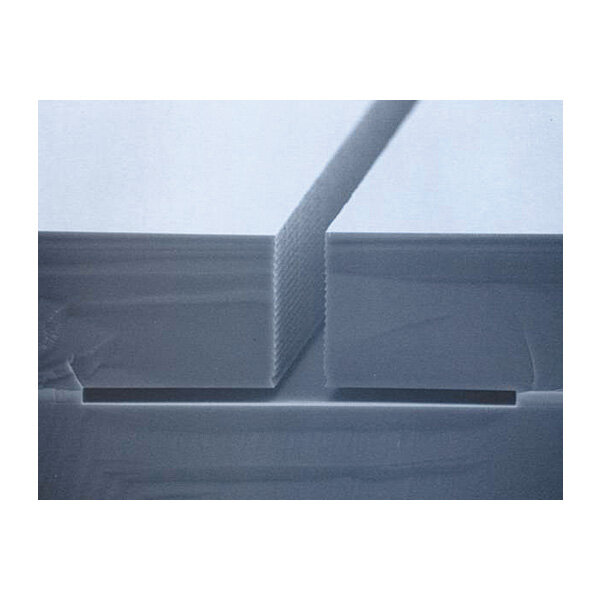

- Gyro sensor structure [Photo provided by SSP]

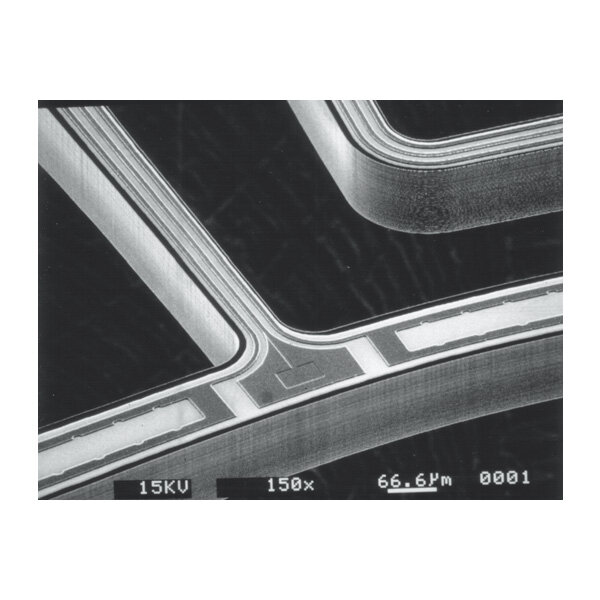

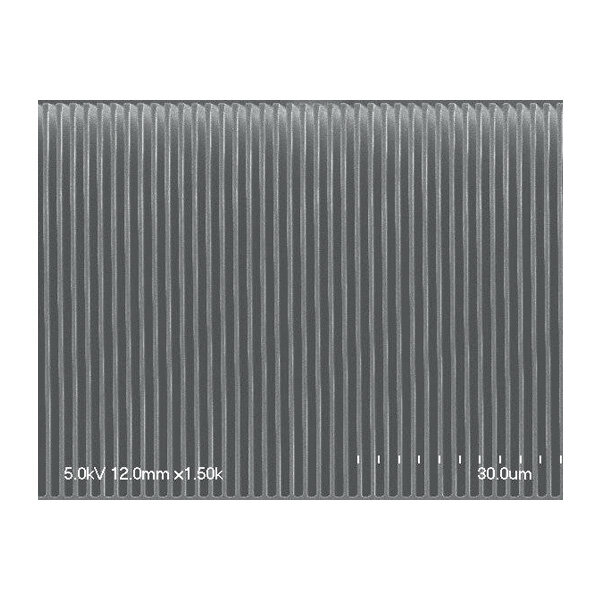

- High aspect ratio etching

Sacrificial layer etching equipment (silicon, silicon oxide film)

The removal of sacrificial layers is a process unique to the manufacture of MEMS with microscopic moving parts. This is an isotropic dry etching system for silicon oxide films that can be processed without causing adhesion of structures that occurs with wet etching.

We offer a lineup of transfer systems ranging from simple manual types to cluster types, and can handle everything from research prototypes to mass production. They are used for a variety of purposes, including silicon microphones and optical devices.

- Silicon oxide film sacrificial layer etching equipment

MLT SLE-Ox

- Silicon oxide film sacrificial layer etching equipment

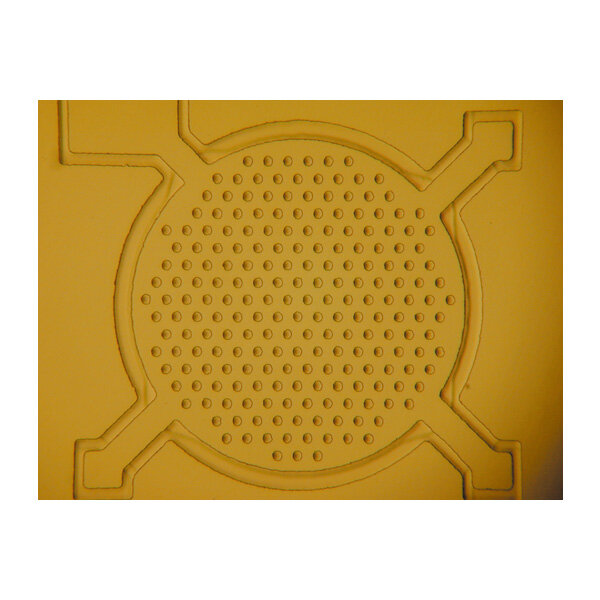

- Silicon microphone structure

[Photo courtesy of Sensfab]

- Silicon microphone structure

- SOI wafer BOX layer etching

[Photo courtesy of Panasonic]

- SOI wafer BOX layer etching

Other manufacturing equipment

We also handle compound and oxide film etching equipment capable of high-speed etching of difficult-to-etch materials such as compound semiconductors and optical devices, as well as plasma deposition equipment that is ideal for forming low-stress silicon nitride films and thick silicon oxide films.

- Compound/Oxide Film Etching Equipment APS Series

- Cetus plasma deposition equipment

- Main Equipment

-

- Oxide/nitride film etching equipment

- SiC etching equipment

- Plasma dicing equipment

- Heat Treatment Device

- Plasma CVD equipment

- Metal film sputtering equipment (PVD)

- Molecular Vapor Deposition (MVD)

- Minimalist Device

Multi-chamber platform

To support mass production and improve productivity, we offer a lineup of vacuum cassette type platforms and atmospheric cassette type platforms that enable high throughput through high-speed transfer.

Multi-chamber configuration is possible; the vacuum cassette type can be equipped with up to three chambers (VPX series) or four chambers (CPX series), while the atmospheric cassette type can be equipped with up to two chambers (DPX series).

- Silicon deep drilling equipment

CPX ASE-Pegasus

- Silicon deep drilling equipment

- Silicon oxide film sacrificial layer etching equipment

VPX SLE-Ox

- Silicon oxide film sacrificial layer etching equipment

- Silicon deep drilling equipment

DPX ASE-Pegasus

- Silicon deep drilling equipment