Other (Valve/Coolant System)Products

- Others (valves/coolant systems)

- SUMIJET X coolant system

Others

(Valve/Coolant System)

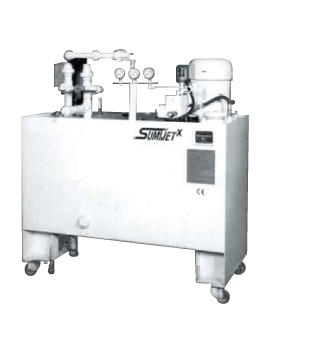

SUMIJET X coolant system

What is SUMIJET X?

Pump + Tank + Valve + Filter unit

Benefits of high-pressure coolant

| 1 | Increased cutting speed. |

|---|---|

| 2 | Streamlining deep hole drilling (improving productivity). |

| 3 | Cooling the workpiece improves the finishing accuracy and machining surface precision. |

| 4 | Cooling extends tool life. |

| 5 | Improved chip crushing and discharge (chips are crushed into chips). |

Features of each SUMIJET X model

SUMIJET X (Series B) (Fabric filter type)

- Multi-layered fabric bag-like filters are arranged in parallel.

- The filter can be replaced by opening and closing the valve even during operation.

- The filter can be removed in a dehydrated state.

- Wide variety of filters available (3u~30u) at low prices.

SUMIJET X (Series C) (Cyclone type)

- Cyclone system - By vortex flow, sludge is discharged from the lower nozzle and clean liquid is discharged from the upper nozzle.

- No maintenance is required, so you will never come into contact with coolant.

- Environmentally friendly as there is no filter disposal. *Oil-based liquids are not recommended as they reduce filter efficiency.

SUMIJET X(Series E) (2-stage filtration method)

- The first stage filter is for coarse filtration.

- The metal element has a pressure resistance of 0.4MP, so it can be cleaned and reused.

- The pressure filtration method allows for forced filtration, and both oil-based and water-soluble liquids can be used.

- The second stage filter has a large filtration area and clogs slowly, so maintenance is less frequent.

SUMIJET X (Series W) (backflow filter cleaning method)

- The filter is periodically back-washed using factory air pressure and clean fluid stored in the reverse tank.

- No maintenance required.

- The filter can be reused, so no waste is produced and it is environmentally friendly. *Please contact us separately if you are using oil-based liquids.